Reinforced Hose Extrusion Line

Description

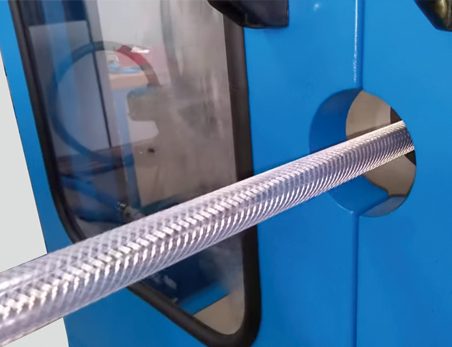

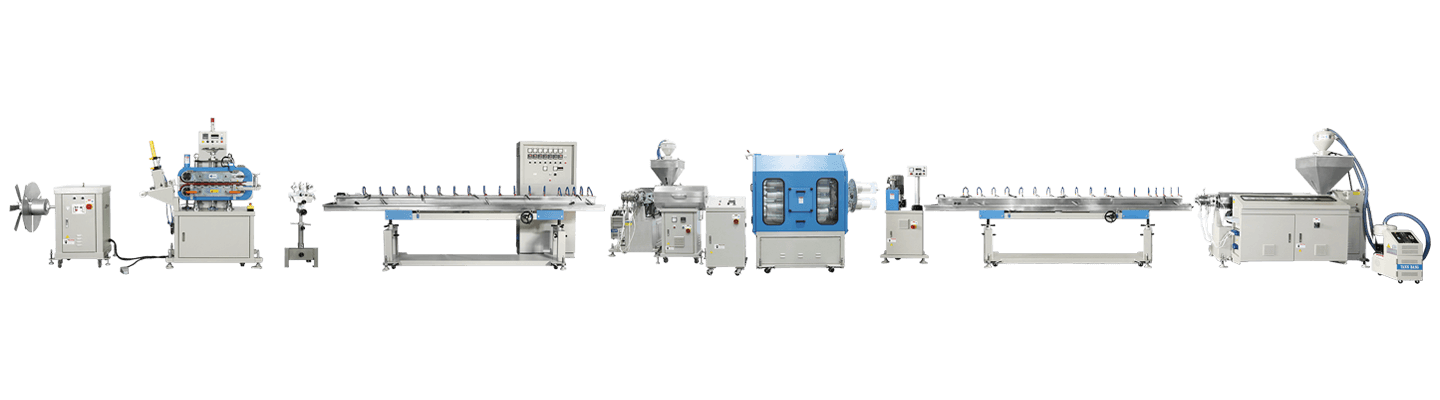

Our PVC reinforced hose extrusion line is specifically designed for producing high-strength reinforced hoses. Built on stable extrusion and precise braiding technology, this line manufactures hoses with excellent pressure resistance, abrasion resistance, and corrosion resistance. The hose typically features a three-layer structure: the inner and outer layers are flexible, durable PVC, while the middle layer is reinforced with high-strength polyester fiber or steel wire, ensuring long-term performance and durability. The design balances flexibility with strength, making it suitable for demanding environments.

Main applications include:

- Garden watering and large-scale agricultural irrigation

- Household water supply, washing machine inlet hoses, and everyday utility hoses

- Air compressor systems, cooling liquid transport, and industrial piping

- Construction sites and large engineering projects requiring high-pressure hoses

- Food, medical, or other hygienic transport applications (customizable upon request)

Key Features

- Extrusion System: Single/double screw design ensures stable plasticization and uniform wall thickness. High-efficiency extruder adapts to various formulations, guaranteeing consistent quality.

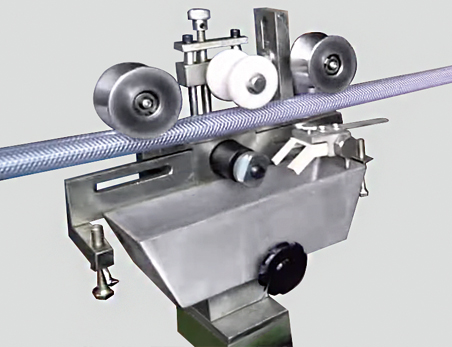

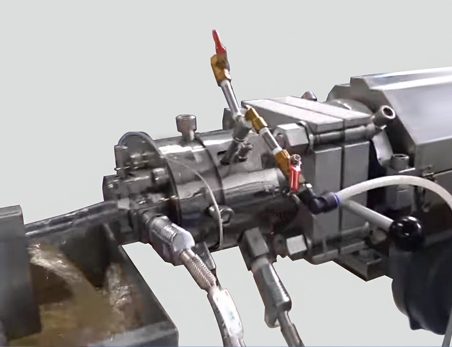

- Braiding Unit: Equipped with high-speed fiber or steel wire braiding machines. Precise braiding significantly improves pressure resistance and tensile strength.

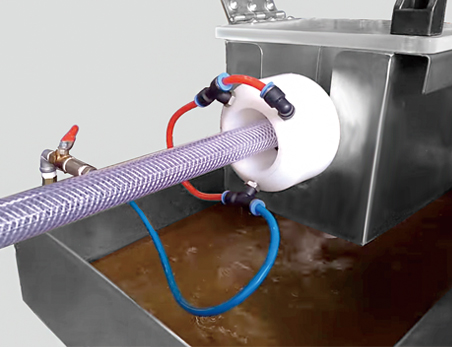

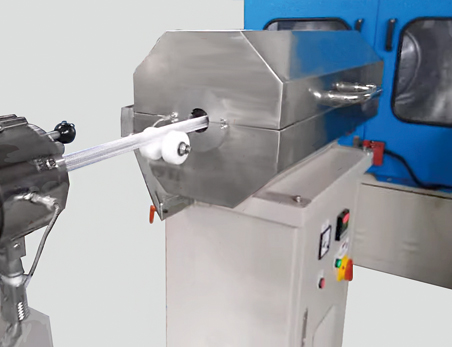

- Cooling & Haul-Off: Stainless steel cooling tank with a stable haul-off unit ensures precise dimensions and prevents deformation during production.

- Cutting & Winding: Fully automatic cutting and winding functions allow different coil sizes or lengths, improving packaging and logistics efficiency.

- Energy Efficiency: Optimized line design minimizes energy consumption and material waste while maintaining maximum productivity.

- Flexible Configuration: Optional co-extrusion units or marking line devices support transparent, colored, or striped hose production.

Specification Range

| Item | Parameter Range |

|---|---|

| Hose Diameter | 6mm – 75mm (approx. 1/4″ – 3″) |

| Braiding Layers | 24 to 64 layers |

| Appearance Options | Transparent / colored, with optional multi-color marking lines |

| Pressure Rating | Multiple levels available upon request |

| Extended Configuration | Optional co-extrusion layers, reinforced cooling tanks, and high-speed winders |

Customization & Services

We provide a complete turnkey solution covering raw material feeding, extrusion, braiding, cooling, haul-off, and winding. Based on factory space, product specifications, and production capacity, we deliver tailored configurations to maximize efficiency. For special requirements, optional automation and smart monitoring systems are available to enhance line stability and ease of operation.

Why Choose Us

- Over 20 years of expertise in extrusion technology

- Exported worldwide with installation and operation records across Asia, Europe, and the Americas

- Local service teams offering prompt technical support and spare parts supply

- Customer-oriented solutions tailored to diverse industry needs

- Proven success across home appliance, construction, agriculture, and industrial sectors, with multiple certifications and recognition