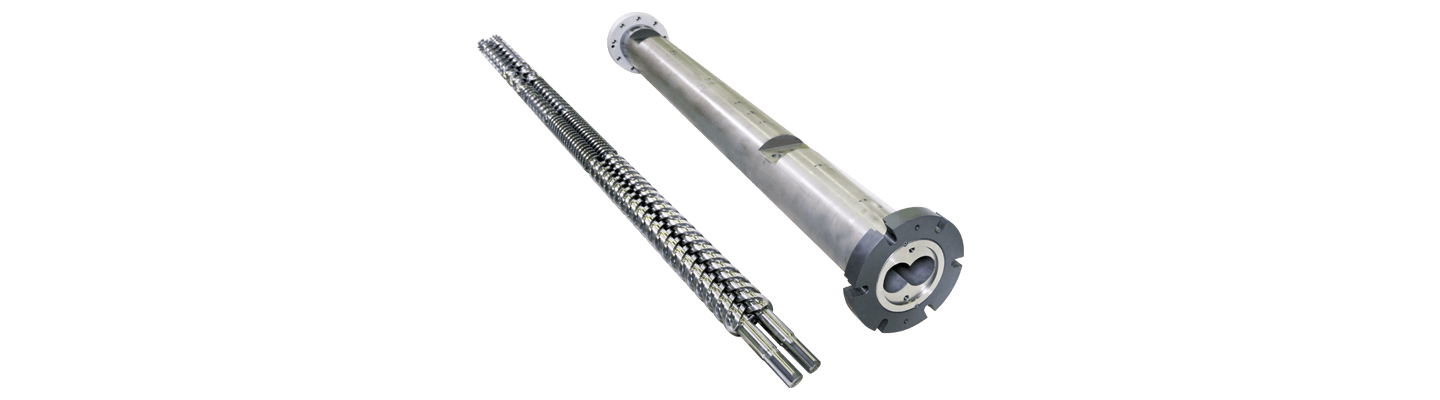

Extruder Screws and Barrels

Description

TwinScrew specializes in the design and manufacturing of extruder screws and barrels, offering single-screw and twin-screw components with diameters up to 132 mm, screw lengths up to 3,700 mm, and barrel lengths up to 4,000 mm. All screws and barrels are made from high-quality alloy steels imported from Germany or Japan, ensuring wear resistance, corrosion resistance, and stability. These components are widely used in plastic extrusion, compounding, injection molding, and rubber processing.

Key Features & Advantages

- Precision Manufacturing Process: Screw production includes blank preparation and annealing, CNC turning, deep-hole drilling for cooling channels, CNC milling of screw geometry, straightening, polishing (surface roughness ≤ Ra 0.8 µm), and final inspection with test reports.

- High-Strength Materials: Options include alloy steel or bimetallic structures with nickel- or tungsten-chromium-based alloys to enhance wear and corrosion resistance, extending service life by 2–3 times, especially for glass fiber-reinforced or filled compounds.

- Optimized Screw Design: Screw flights and channel depths are tailored to raw material and process requirements, ensuring uniform melting, stable melt pressure, and improved throughput and product quality.

- Precision Barrel Engineering: Barrels undergo deep-hole boring, CNC finishing, honing, and optional treatments such as nitriding or bimetallic liners to increase durability.

- Strict Quality Control: Each screw and barrel undergoes dimensional checks, concentricity testing, and is delivered with inspection reports to guarantee precise fit and smooth operation.

- High Efficiency & Reliability: Advanced machining and material selection ensure stable performance under high temperature and pressure, reducing downtime and maintenance costs while increasing productivity and consistency.

Technical Specifications

| Category | Diameter Range | Length | Notes |

|---|---|---|---|

| Single Screw | Ø30 – Ø370 mm | Up to 5,000 mm | For single screw extruders or pelletizers; customizable lengths |

| Twin Screw | Ø30 – Ø150 mm | Up to 5,000 mm | For co-rotating or counter-rotating twin-screw extruders |

| Single Bore Barrel | Ø50 – Ø370 mm | Up to 5,000 mm | With nitriding or bimetallic liners for single-screw systems |

| Twin Bore Barrel | Ø30 – Ø150 mm | Up to 5,000 mm | For parallel twin-screw systems with customized liner materials |

Customization & Services

- Screw & Barrel Design: Tailored designs for screw pitch, channel depth, L/D ratio, and compression ratio according to raw material and application.

- Surface Treatments: Options include nitriding, hard chrome plating, tungsten carbide coating, and bimetallic lining for enhanced durability.

- Temperature Control: Internal cooling channels can be integrated for precise thermal management and improved processing efficiency.

- Repair & Refurbishment: Services include regrinding, relining, and refurbishment to extend equipment life and minimize downtime.

- Technical Support: Training, process consulting, and after-sales maintenance ensure reliable long-term operation.

Why Choose Us

- Superior Quality: Premium imported materials combined with advanced CNC machining ensure precision and durability.

- Expertise: Years of experience in screw and barrel manufacturing with applications across plastics and rubber extrusion.

- Customization: Fully tailored solutions for different compounds, production capacities, and wear conditions.

- After-Sales Service: Comprehensive installation, maintenance, and spare parts supply to support stable, long-term production.

Related Video

- For thirty-two years, TwinScrew has been designing and manufacturing fully computerized lines for pipe extrusion. PVC pipe extrusion line is one of our specialized items.

- The Parallel twin screw extruder has newly developed for its technologies in UPVC pipe extruded by increasing in the drive torques and innovative solutions to problems in politicizing, screw thermoregulation by self-regulating, sealed water cooling system, vacuum scavenging system and melt pressure control.

- One line equipment includes Main Extruder,Vacuum Spray Cooling Tank,Haul-off Machine,Automatic Traveling Saw, Automatic Belling Machine (or Down Table).

The concept of the spider die guarantees outstanding product characteristic for PVC material.

The benefits:

- Ideal residence time profile over the whole flow cross-section

- Homogeneous melt distribution

- Simple and reliable handling