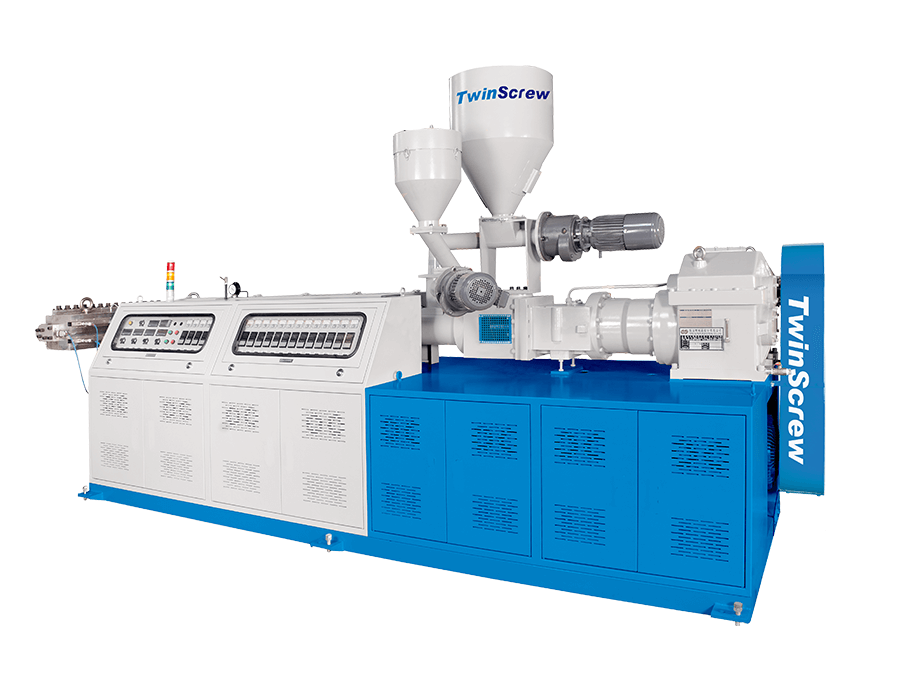

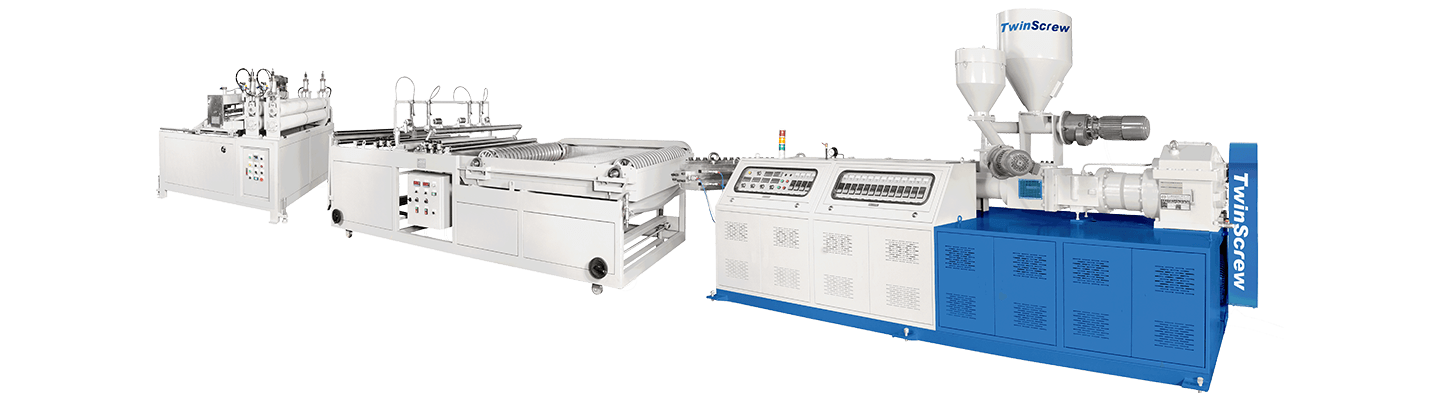

PVC Waterstop Profile Extrusion Line

Description

TwinScrew invests decades to improve the facility for getting better performance every time at water stop profile extrusion. It requests extremely the tolerance of profile dimension to be fully qualified with any international standard; well homogenized from raw material and its formula to make the final products durable. In addition, we offer customized service to satisfy our customers.

Per our experience in this field, we believe that TwinScrew is one of the best choices for customers who looks for advanced equipment.

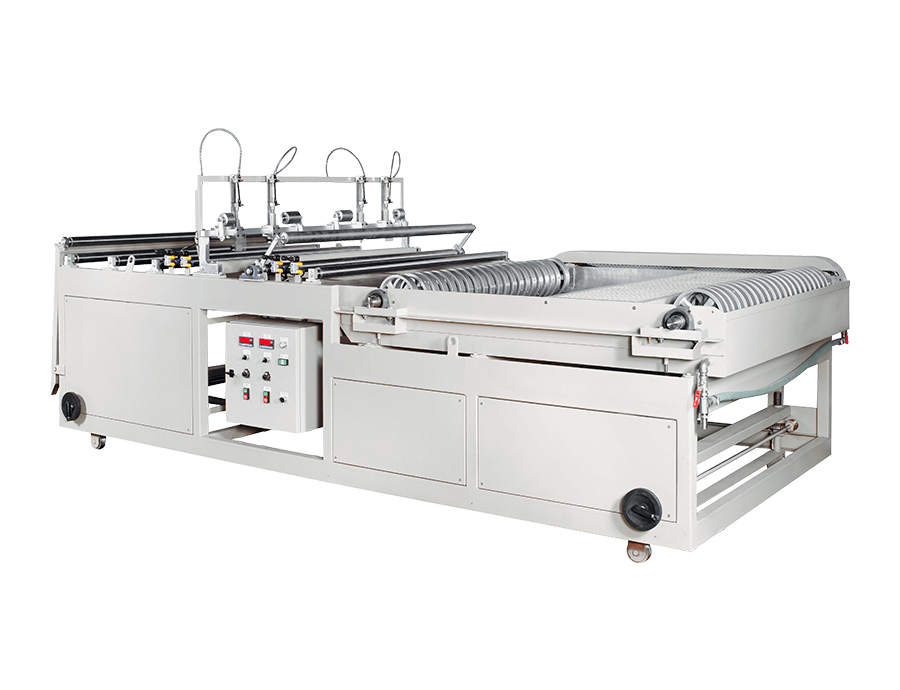

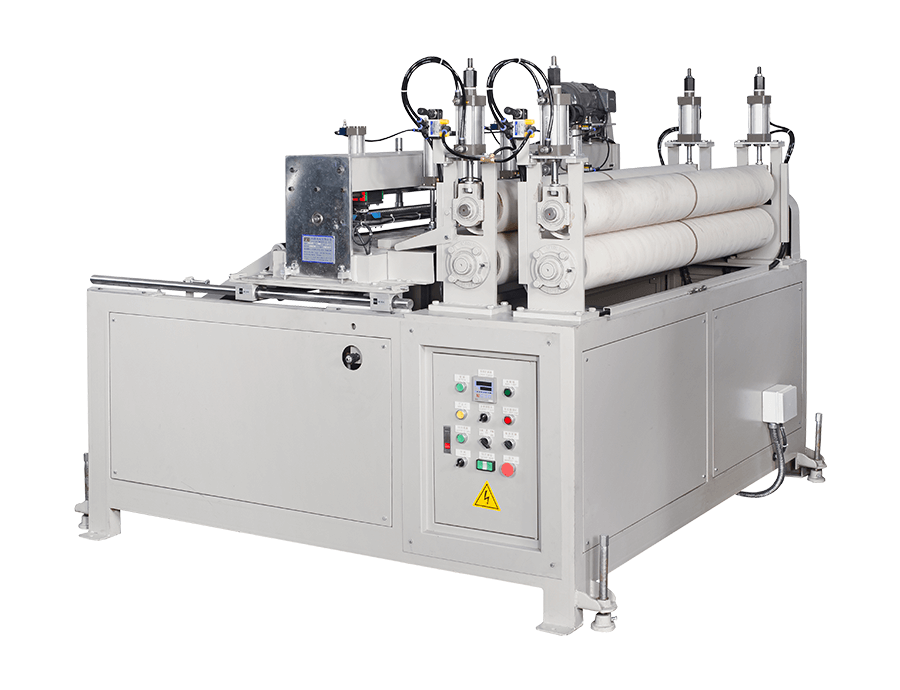

This kind of equipment can be used to produce for also other types of large volume profiles, like door panels, foamed PVC sheets, hollow roofing, corrugated sheet, etc. One completed line includes Main Extruder, Extrusion Tool, Calibrating System, Calibrating Table, Profile Caterpillar Haul-off, and Saw. welcome to contact us to discuss your project.

Per our experience in this field, we believe that TwinScrew is one of the best choices for customers who looks for advanced equipment.

This kind of equipment can be used to produce for also other types of large volume profiles, like door panels, foamed PVC sheets, hollow roofing, corrugated sheet, etc. One completed line includes Main Extruder, Extrusion Tool, Calibrating System, Calibrating Table, Profile Caterpillar Haul-off, and Saw. welcome to contact us to discuss your project.

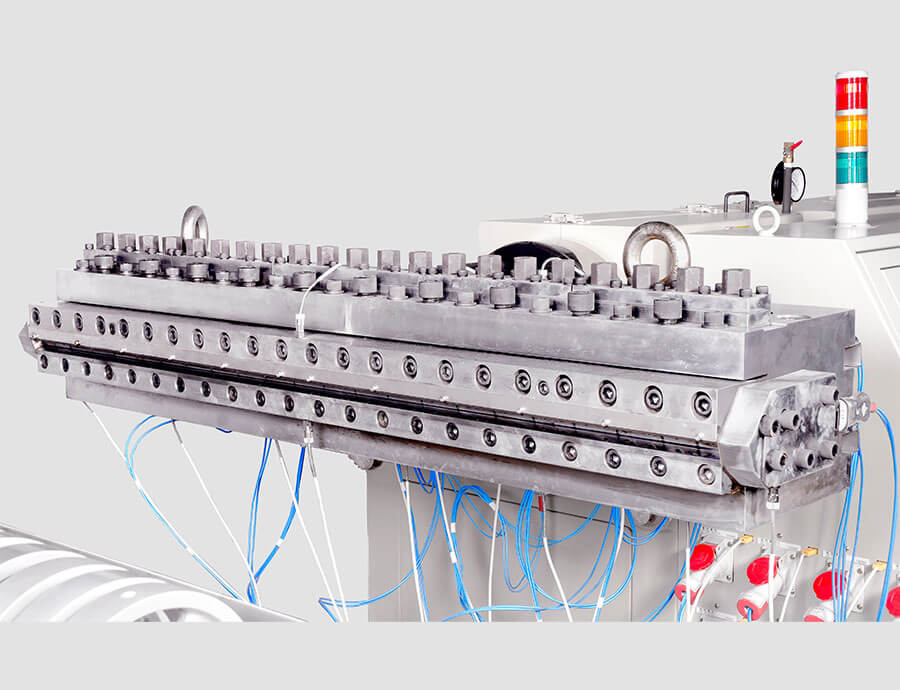

Extrusion die is designed segment type by stainless steel alloy and regulated through proper heating zones. Lifetime is durable and easy to assemble.