PVC Ceiling Machine Guide: Features, Applications, and Buying Tips

- What is a PVC Ceiling Machine and How Does It Work?

- Key Features of a PVC Ceiling Machine for Efficient Panel Production

- Applications of PVC Ceiling Machines in Residential and Commercial Projects

- PVC Ceiling Panels vs. Alternatives: Why PVC is Winning

- Twin-Screw vs. Single-Screw Extruders for Ceiling Machines

- Common Extrusion Challenges and Solutions

- Case Study: How a PVC Ceiling Machine Improved Production Efficiency

- PVC Ceiling Machine Certifications & Global Quality Assurance

- Technical Specifications of PVC Ceiling Machine

- Alternative to PVC Ceiling Machine: Large Volume Profile Extrusion Line

- Smart Manufacturing: The Future of PVC Ceiling Production

- TwinScrew’s Commitment to PVC Extrusion Technology

- Frequently Asked Questions About PVC Ceiling Machines

- Why a PVC Ceiling Machine Is a Strategic Investment

The global construction industry is shifting rapidly toward cost-effective, durable, and easy-to-install building materials. Among these, PVC ceiling panels have emerged as a strong alternative to traditional plaster, gypsum, and wood ceilings. Their waterproof, lightweight, and low-maintenance properties make them ideal for residential, commercial, and industrial projects.

At the heart of this growing market is the PVC Ceiling Machine—a critical piece of extrusion equipment that transforms raw PVC compounds into high-quality ceiling panels. Choosing the right machine is not just a technical decision. It is also a strategic investment in production efficiency, market competitiveness, and long-term profitability.

What is a PVC Ceiling Machine and How Does It Work?

Before considering performance and ROI, it’s important to understand the fundamentals of the technology. A PVC ceiling machine is not a single unit but a complete extrusion system designed for precision panel manufacturing.

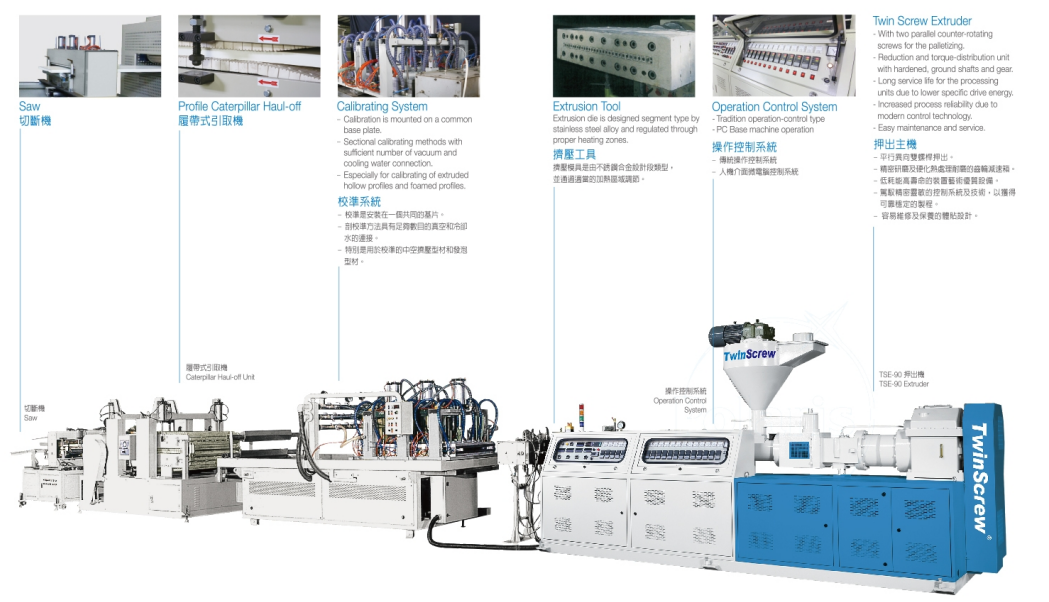

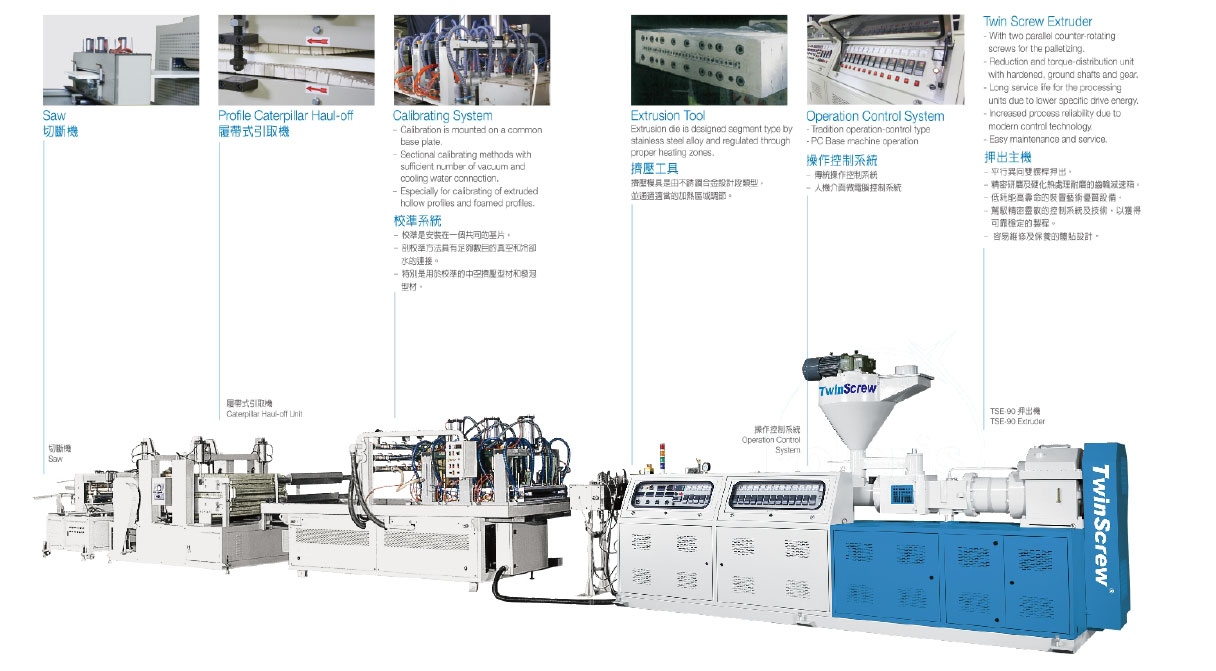

It typically includes:

- Extruder (Twin-Screw) – Melts and homogenizes PVC with additives.

- Extrusion Die – Shapes molten PVC into precise panel profiles.

- Calibration & Cooling System – Stabilizes and cools panels to avoid warping.

- Haul-off Unit – Pulls profiles at a consistent speed.

- Cutting Unit – Cuts finished panels to required lengths.

Unlike general-purpose plastic extruders, ceiling machines are specifically engineered for panel accuracy and stability, ensuring flatness, dimensional precision, and decorative surface compatibility.

With the basics established, let’s explore why manufacturers choose a PVC Ceiling Machine as the foundation for efficient production.

Watch how a PVC ceiling machine works in this demonstration video:

Key Features of a PVC Ceiling Machine for Efficient Panel Production

The right features in a PVC ceiling machine can significantly improve output quality and operational efficiency. These advantages are what separate a standard extrusion system from one built for long-term success.

- Flexible Output Range – Supports ceiling panel production up to 800mm in width.

- Energy-Saving Design – Optimized heating and drive systems reduce power consumption.

- Durable Construction – Heavy-duty design with Siemens, ABB (including B&R automation), Schneider, and Fuji components ensures longevity.

- Automated Controls – PLC and touchscreen integration minimize operator workload.

- Dimensional Accuracy – Vacuum calibration prevents warping and bowing.

- Flexible Finishing Options – Supports lamination, hot stamping, or UV coating for decorative surfaces.

Now that we’ve reviewed the machine’s capabilities, let’s look at where PVC ceiling panels are commonly applied and why global demand continues to rise.

Applications of PVC Ceiling Machines in Residential and Commercial Projects

The global appeal of PVC ceiling panels lies in their adaptability across multiple industries. A ceiling machine enables factories to serve diverse markets, from basic residential builds to complex commercial projects.

- Residential Projects – bathrooms, kitchens, basements (moisture-prone areas).

- Commercial Spaces – hotels, malls, offices, healthcare facilities.

- Export Markets – strong demand in Asia-Pacific, Middle East, and Africa due to affordability and durability.

With such wide adoption, it becomes clear why PVC ceiling panels are rapidly replacing traditional materials—a topic we'll examine in detail in the next section.

PVC Ceiling Panels vs. Alternatives: Why PVC is Winning

Not all ceiling materials are created equal. Buyers often compare PVC panels with traditional gypsum boards or wooden ceilings, and the performance differences are striking.

| Feature | PVC Ceiling Panels | Gypsum Board | Wooden Ceilings |

|---|---|---|---|

| Durability | High, impact-resistant | Fragile, cracks easily | Strong but vulnerable to termites |

| Moisture Resistance | 100% waterproof | Absorbs water, sags | Swells and rots |

| Maintenance | Easy, wipe-clean | Requires repainting | Needs polishing |

| Cost | Lower long-term cost | Higher maintenance cost | Expensive |

| Installation | Fast, dust-free | Slow, messy | Labor-intensive |

PVC ceiling panels consistently outperform alternatives in both cost efficiency and lifecycle durability, making them the material of choice in modern construction.

But material choice alone is not enough—manufacturers also need the right extrusion technology to ensure consistent output, which brings us to extruder selection.

Twin-Screw vs. Single-Screw Extruders for Ceiling Machines

When it comes to extrusion technology, not all machines deliver the same level of performance. The choice between single-screw and twin-screw extruders directly impacts product quality, production stability, and ROI.

| Feature | Single-Screw Extruder | Twin-Screw Extruder |

|---|---|---|

| Mixing Capability | Limited | Superior mixing & homogenization |

| Material Flexibility | Standard PVC only | PVC with fillers, additives, recycled material |

| Output Quality | Variable | Consistent dimensional accuracy |

| Throughput | Moderate | Higher throughput at stable quality |

For ceiling panels, twin-screw extruders are the clear choice. They provide consistent dimensional accuracy, handle recycled or filled materials, and achieve higher productivity.

Now that we’ve seen the role of extruder choice, let’s look at common challenges in ceiling extrusion—and how advanced machines overcome them.

Common Extrusion Challenges and Solutions

Even the most advanced production lines can face defects if not properly engineered. TwinScrew’s PVC ceiling machines are designed to proactively address these challenges.

- Warping or Bowing → Controlled vacuum calibration & cooling.

- Surface Defects → Optimized die design ensures uniform flow.

- Air Bubbles or Voids → Degassing zones in twin-screw extruders remove trapped gases.

- Dimensional Inaccuracy → Precision haul-off and cutting units maintain tolerances.

These solutions minimize downtime, reduce material waste, and improve profitability. To better illustrate the impact of modern extrusion technology, here’s a real-world example of a factory upgrade using TwinScrew equipment.

Case Study: How a PVC Ceiling Machine Improved Production Efficiency

A factory in Southeast Asia previously relied on outdated equipment, which often produced panels with inconsistent quality while consuming excessive energy.

After switching to TwinScrew’s PVC Ceiling Machine:

- Product quality improved significantly, with smoother surfaces and better dimensional consistency.

- Energy consumption dropped by 25%.

- Many clients report achieving ROI within a relatively short period, depending on raw materials, labor, and production scheduling.

This case highlights how modern extrusion technology can transform factories into profit centers, rather than cost burdens.

Of course, efficiency gains are only sustainable if machines meet international quality standards. Let’s review the certifications that back every TwinScrew system.

PVC Ceiling Machine Certifications & Global Quality Assurance

Every machine is backed by international standards:

- CE Certification (European safety compliance)

- ISO 9001:2015 (quality management)

- Siemens, ABB (including B&R automation), Schneider, and Fuji Components (trusted global brands)

Technical Specifications of PVC Ceiling Machine

Below are the most common PVC ceiling machine models designed to meet different production capacities:

| Model | Screw Diameter (mm) | L/D Ratio | Drive Power | Screw R.P.M | Barrel Heater Power (kW) | Total Power (kW) | Max Output (kg/h) | Dimensions L×W×H (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| TSE-75 | Ø75 | 25:1 | 40 HP | 42 | 27 kW | 64 kW | 200–300 | 3960 × 1400 × 2360 | 3600 |

| TSE-90 | Ø90 | 25:1 | 75 HP | 42 | 37 kW | 90 kW | 300–500 | 4670 × 1590 × 2420 | 4400 |

| TSE-110 | Ø107 | 25:1 | 100 HP | 42 | 48 kW | 130 kW | 500–700 | 5140 × 1750 × 2480 | 6700 |

| TSE-130 | Ø132 | 25:1 | 125 HP | 42 | 79 kW | 205 kW | 950–1200 | 6380 × 2260 × 2700 | 9500 |

Discover detailed specifications, configurations, and customized solutions in our complete product catalog.[Download Catalog]

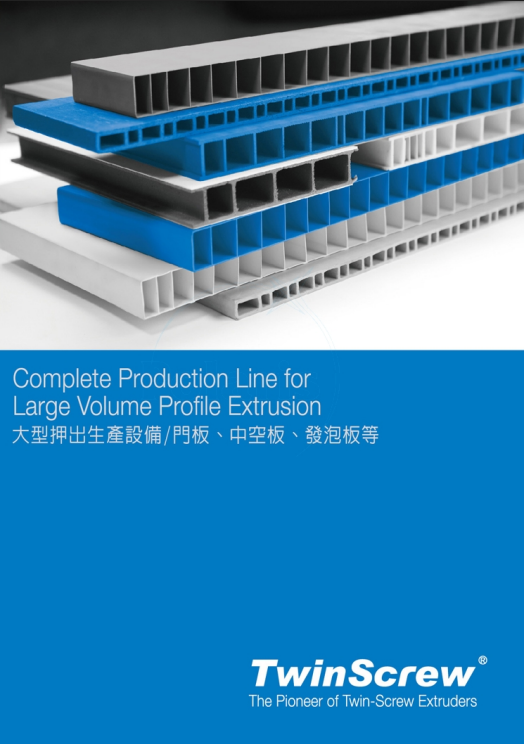

Alternative to PVC Ceiling Machine: Large Volume Profile Extrusion Line

For manufacturers seeking more versatility, our Large Volume Profile Extrusion Line is designed for windows, doors, gutters, and decking—in addition to ceiling panels.

With versatility addressed, the next question is how factories can future-proof their production systems.

Smart Manufacturing: The Future of PVC Ceiling Production

The ceiling panel industry is undergoing a transformation. With growing demand for automation, energy efficiency, and Industry 4.0 integration, the factories of tomorrow will look very different from today.

TwinScrew’s machines are designed for:

- PLC Real-Time Monitoring

- Predictive Maintenance

- Energy-Efficient Drive Systems

- Fast Mold Changeovers

These features not only optimize production but also position factories to remain competitive as market expectations evolve.

This forward-looking approach is rooted in TwinScrew’s decades-long commitment to extrusion technology.

TwinScrew’s Commitment to PVC Extrusion Technology

With over 30 years of twin-screw innovation, TwinScrew has supplied 3,000+ systems across 40+ countries. Our in-house engineering of screws, dies, and gearboxes ensures unmatched precision, while our global service network delivers 24/7 support.

We don’t just deliver machines—we deliver partnerships, expertise, and long-term success. For ceiling panel manufacturers, that means sustainable growth, lower operating costs, and a competitive edge.

With technology, certifications, and case studies covered, let’s close with answers to some of the most common buyer questions.

Frequently Asked Questions About PVC Ceiling Machines

Q1. Can one machine handle multiple panel sizes?

Yes, interchangeable molds support up to 800mm widths.

Q2. Do you provide installation and training?

Absolutely. Our engineers ensure your team is fully equipped for production.

Q3. What is the typical ROI timeline?

ROI timeline can vary widely depending on multiple factors, such as the type of raw materials used, labor allocation and efficiency, production scheduling, and of course, the machine model and configuration selected. With the right combination of these elements, many clients are able to reach profitability in a relatively short period.

Why a PVC Ceiling Machine Is a Strategic Investment

A PVC Ceiling Machine is more than just production equipment—it represents the foundation of a profitable ceiling panel business. With twin-screw extrusion technology, energy-efficient systems, and automation-ready controls, manufacturers can achieve higher output, lower operating costs, and consistent product quality.

By investing in the right PVC ceiling machine, you are not only securing immediate production efficiency but also building long-term competitiveness in a growing global market.

Ready to upgrade your production line? Request a Quote and discover how our PVC Ceiling Machines can accelerate your ROI.

Related Articles