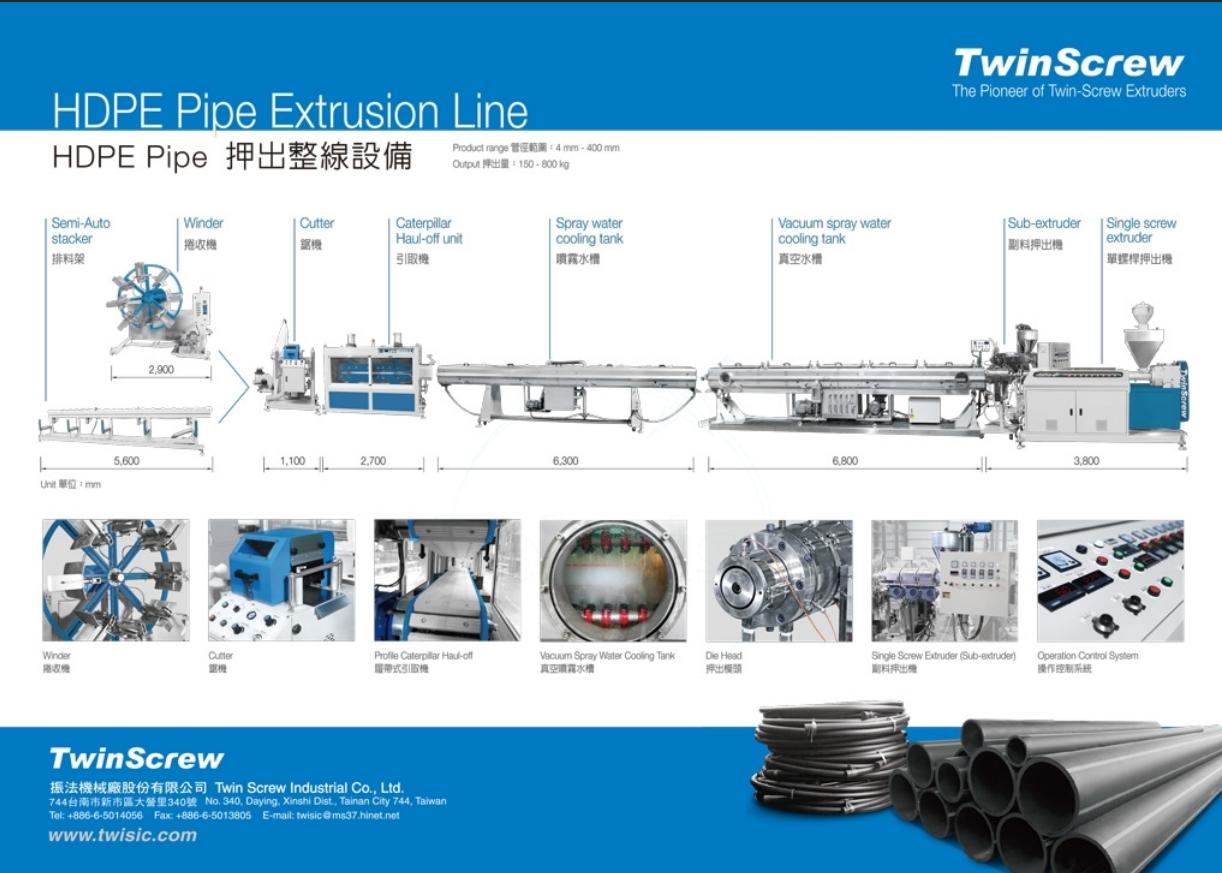

HDPE Pipe Extrusion Line – Process, Components, and Advantages of a Single-Screw System

- Understanding the HDPE Pipe Extrusion Process

- Main Components of an HDPE Pipe Extrusion Line

- Technical Highlights

- HDPE Pipe Extrusion Line: Product Range & Output Capacity

- Process Optimization and Precise Control

- HDPE Extrusion Solutions: Certified Quality & Global Presence

- Why Choose Twin Screw’s Single-Screw HDPE Pipe Extrusion Line

- Applications of HDPE Pipes

- Why Choose a Taiwan Manufacturer

- Achieve Long-Term Success with the Right HDPE Pipe Extrusion Partner

High-density polyethylene (HDPE) pipes play a vital role in modern infrastructure, serving applications from water and gas supply to cable protection and irrigation.At the heart of every high-quality HDPE pipe lies a critical technology: the HDPE pipe extrusion line, also known as an HDPE pipe production line.This advanced system uses a high-performance HDPE pipe extrusion machine to transform raw HDPE pellets into durable, precisely shaped pipes ready for demanding applications.

This guide provides a complete overview of the HDPE pipe extrusion process, explains each major component, and highlights why a single-screw system from Twin Screw Industrial is a preferred choice for manufacturers worldwide.

Understanding the HDPE Pipe Extrusion Process

The HDPE pipe production line is a continuous manufacturing system that converts raw materials into finished pipes with consistent dimensions and strength.Here’s how the process works step by step:

-

Feeding

HDPE pellets are automatically fed into the single-screw HDPE pipe extrusion machine through a precise gravimetric dosing system.

-

Melting and Homogenizing

Inside the single-screw extruder, the pellets are uniformly melted, pressurized, and homogenized under controlled temperature and screw design.

-

Shaping

The molten polymer is pushed through a die head, forming the desired pipe profile.

-

Cooling and Calibration

The pipe passes through a vacuum calibration tank and spray cooling section for dimensional precision and surface smoothness.

-

Haul-Off and Cutting

A caterpillar-style haul-off unit maintains stable traction, followed by an automatic cutting system for accurate pipe length.

-

Winding or Stacking

Smaller pipes are coiled automatically, while large-diameter pipes are stacked or conveyed for packaging.

Each stage in the HDPE pipe extrusion line works in harmony to achieve stable output, precise wall thickness, and smooth surface finish—meeting the stringent quality demands of HDPE pipe applications.

Main Components of an HDPE Pipe Extrusion Line

Each component of the HDPE pipe extrusion line contributes to stable, efficient operation. Below we break down every major part — from the extruder to the winder — and explain how Twin Screw Industrial’s engineering ensures reliability and precision.

-

Single-Screw Extruder

The extruder is the powerhouse of the entire HDPE pipe extrusion line.Twin Screw’s high-performance single-screw HDPE pipe extrusion machine ensures stable melt temperature and excellent plasticizing efficiency.Its optimized screw and barrel design provide uniform material flow and consistent wall thickness, even under continuous operation.

HDPE pipe single-screw extruder / HDPE pipe extrusion machine

-

Co-Extruder (Optional)

For advanced production, a co-extruder can be integrated with the main HDPE pipe production line to create multi-layer or striped pipes.This enables flexible customization for strength, insulation, or color marking.

co-extrusion for HDPE pipe / multilayer extrusion system

-

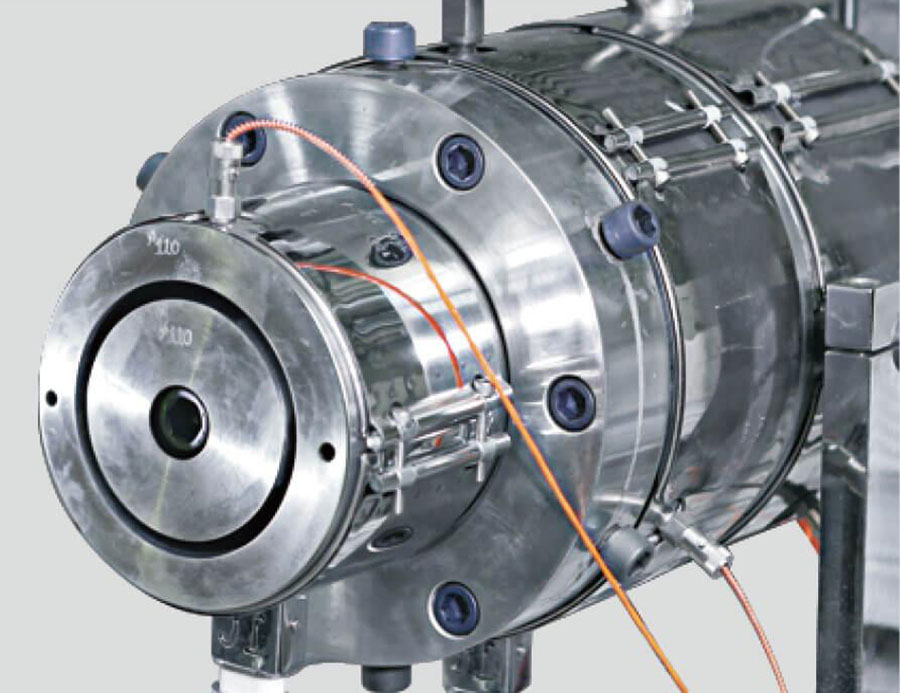

Die Head

Constructed from high-strength alloy steel, the die head features optimized flow channels and temperature control for uniform melt distribution.It ensures smooth inner walls and precise pipe diameters.

HDPE pipe extrusion die head / extrusion die design

-

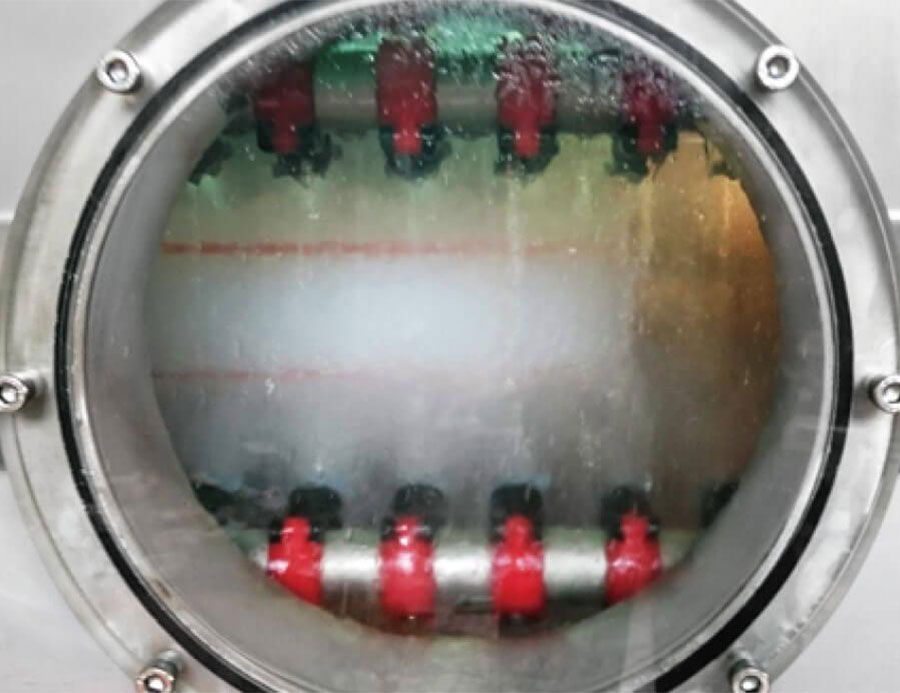

Two-Stage Cooling System (Vacuum + Spray)

After extrusion, the hot pipe enters a vacuum calibration tank, followed by a secondary cooling tank.This two-stage cooling setup improves roundness, dimensional accuracy, and surface finish.

vacuum calibration tank / two-stage cooling for HDPE pipe

-

Caterpillar Haul-Off Unit

The haul-off unit gently pulls the pipe at a synchronized speed.Twin Screw’s dual-belt traction design maintains consistent tension and prevents deformation.

caterpillar haul-off / pipe pulling unit

-

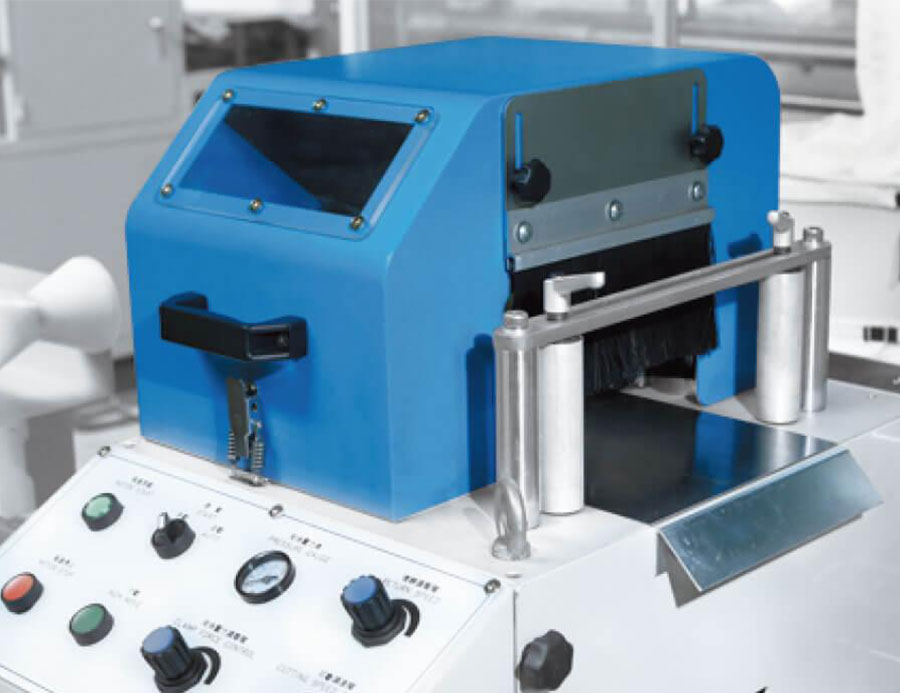

Cutting Unit

The automatic cutting machine ensures clean, burr-free cuts at high speed.Equipped with digital control and a safety cover, it provides precise length accuracy for every pipe.

HDPE pipe cutting machine / automatic pipe cutter

-

Pipe Winder & Stacker

For small-diameter pipes, a pipe winder coils finished pipes for easy handling, while a semi-automatic stacker manages larger diameters.

HDPE pipe winder / semi-auto stacker / pipe coiling system

-

Operation Control System

The PLC + HMI platform serves as the brain of the HDPE pipe production line, offering real-time monitoring of temperature, pressure, and line speed.Optional IoT integration allows remote control, energy tracking, and data logging.

extrusion line PLC control / IoT monitoring system

Technical Highlights

All components in Twin Screw’s HDPE pipe extrusion line are engineered for energy efficiency, high output, and long service life.The integration of single-screw extrusion, precision die design, and automated downstream units makes this system both cost-effective and technologically advanced.

HDPE Pipe Extrusion Line: Product Range & Output Capacity

For procurement and planning, capacity and diameter coverage matter. Twin Screw’s extrusion systems handle a broad range of HDPE pipe sizes and outputs, making them adaptable to diverse market requirements. The HDPE Pipe Extrusion Line covers diameters from 4 mm to 400 mm, with output capacities of 150–800 kg/h, depending on configuration and pipe size.This flexibility enables manufacturers to produce everything from small flexible conduit pipes to large-diameter pressure pipes — all within a single modular system.

Beyond general specifications, process engineers also focus on optimizing key parameters to ensure stable and efficient production.

| Pipe Diameter Range | Output Capacity | Typical Applications |

|---|---|---|

| 32 mm – 75 mm | 100–250 kg/h | Micro irrigation, cable conduits |

| 90 mm – 150 mm | 150–250 kg/h | Water supply, pressure pipes |

| 110 mm – 250 mm | 450–650 kg/h | Municipal, industrial |

| 250 mm – 400 mm | 650–800 kg/h | Large-diameter water and gas mains |

This modular HDPE pipe production line covers a broad range of diameters and applications—ideal for both small conduit pipes and large municipal systems.

(Compare this to rigid PVC pipe capacities in How to Choose the Best PVC Pipe Extrusion Line.)

Process Optimization and Precise Control

Precise control of process parameters is key to achieving consistent pipe quality and reducing material waste. Given that HDPE extrusion often faces challenges such as ovality, surface roughness, and melt fracture, fine-tuning parameters is crucial. To achieve optimal performance, engineers must focus on optimizing the following key extrusion variables:

- Thermal Control: Temperature zones (extruder, die head, vacuum tank), melt pressure, and cooling rate.

- Mechanical Control: Screw speed and torque settings, and haul-off speed synchronization.

Twin Screw's advanced PLC and HMI systems—combined with properly selected screw L/D ratios (commonly 30:1 to 36:1 depending on output and resin)—ensure dimensional accuracy, excellent surface finish, and reduced scrap rates.

| Parameter | Recommended Range | Function |

|---|---|---|

| Barrel Temperature | 180–210 °C | Ensures uniform melting |

| Die Temperature | 200–220 °C | Controls surface smoothness |

| Vacuum Pressure | 0.08–0.12 MPa | Stabilizes diameter accuracy |

| Cooling Water Temperature | 15–20 °C | Prevents surface stress |

| Haul-Off Speed | 0.8-20 m/min | Determines wall thickness |

Proper tuning of the HDPE pipe production line ensures dimensional stability, smooth surface quality, and extended machine lifespan.

For insight into sustainable compounding and energy-efficient processing, see PVC Twin Screw Extruders: An Innovative Solution to Sustainable Manufacturing.

You can also refer to How to Choose the Best PVC Pipe Extrusion Line for more practical process evaluation tips.

HDPE Extrusion Solutions: Certified Quality & Global Presence

Beyond technical design, certification and global experience demonstrate the reliability of Twin Screw’s extrusion solutions.Twin Screw Industrial is ISO 9001 certified and CE-compliant, with extrusion lines operating in over 45 countries. With over three decades of engineering experience, Twin Screw continues to advance HDPE extrusion technology, supplying dependable systems that are trusted by manufacturers across Asia, Europe, the Middle East, and South America.

Why Choose Twin Screw’s Single-Screw HDPE Pipe Extrusion Line

Beyond understanding the process and components, selecting the right extrusion line partner is crucial for long-term success. Here’s why Twin Screw remains the preferred choice for manufacturers worldwide:

- Stable Melt Flow: Optimized single-screw design ensures consistent plasticizing and output.

- Energy Efficiency: Lower power consumption through advanced thermal control.

- Flexible Configurations: Supports single-layer or co-extruded stripe pipes.

- Automation & IoT Ready: Real-time process monitoring and remote data access.

- Turnkey Solution: Complete HDPE pipe production line integration from feeding to winding.

Twin Screw’s single-screw systems combine engineering precision, operational simplicity, and long-term durability, making them a top choice for global pipe manufacturers.

Applications of HDPE Pipes

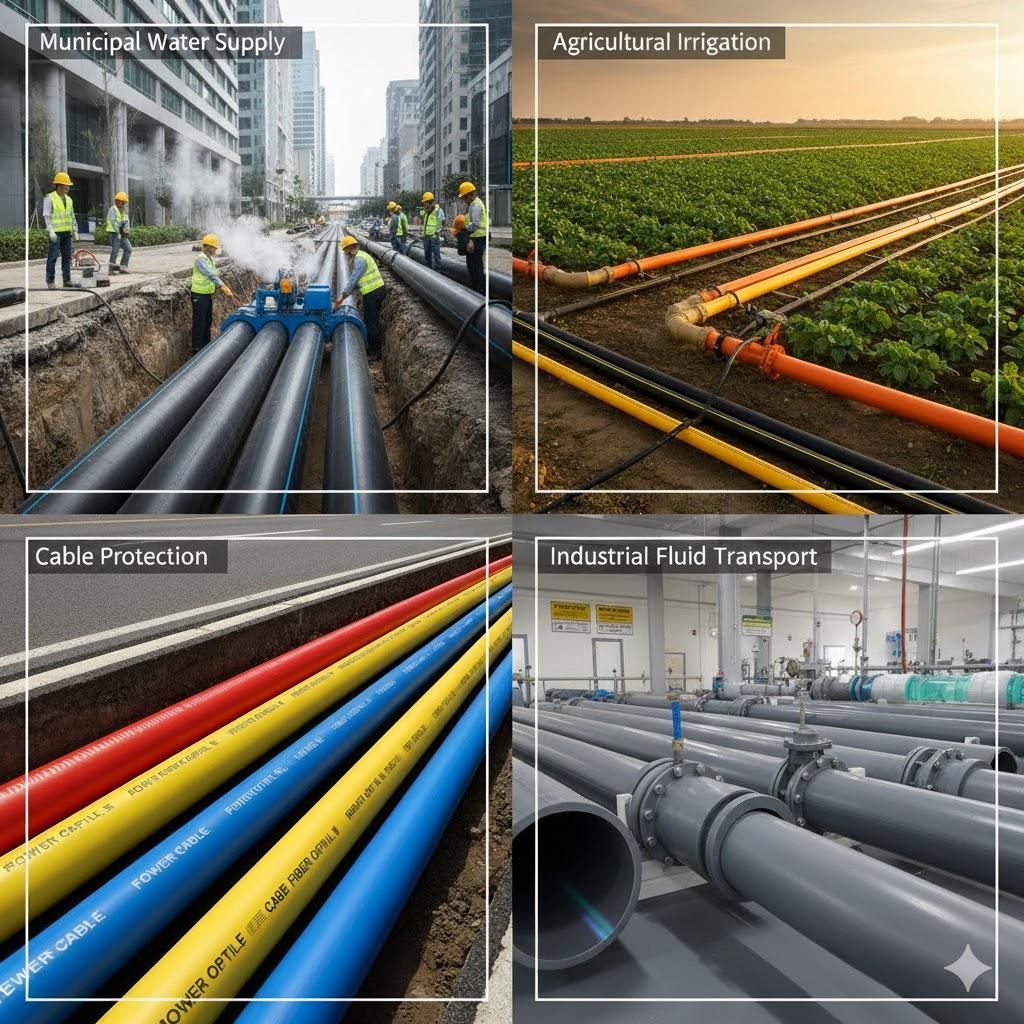

Pipes produced by Twin Screw’s HDPE pipe extrusion line are widely used in municipal water and gas supply systems—and this demand continues to grow alongside global infrastructure investment trends, as highlighted in infrastructure-driven demand for HDPE pipe extrusion machines.

- Municipal water and gas supply systems

- Agricultural irrigation and drainage

- Industrial fluid and chemical transport

- Electrical and communication conduits

- Sewage and wastewater management

Each application demands precise control and stable performance — both ensured by Twin Screw’s HDPE pipe extrusion machines.

Why Choose a Taiwan Manufacturer

Taiwan is globally recognized for its precision machinery and dependable service. Compared to lower-cost regions, Taiwanese HDPE pipe production lines deliver:

- Greater stability and longer lifespan

- Energy-efficient operation

- Comprehensive after-sales and spare-parts support

- Compliance with ISO and CE standards

As a Taiwan-based manufacturer, Twin Screw Industrial combines advanced engineering with customer-oriented service to support long-term success.

Achieve Long-Term Success with the Right HDPE Pipe Extrusion Partner

Whether you’re exploring the HDPE pipe extrusion process, evaluating key components, or comparing global suppliers,Twin Screw Industrial offers a complete solution built on precision engineering, stable output, and service that supports long-term productivity.

Selecting the right HDPE pipe extrusion line partner drives efficiency, material savings, and product quality.Twin Screw supports customers from design and installation to operator training and after-sales service.

Looking for a dependable HDPE pipe extrusion line or co-extrusion system? Contact us today for a customized solution that fits your production goals.

Related Articles