High-Precision Profile Extrusion Guide : Engineering Stability, Quality Control & ROI for Modern Production

Profile extrusion is now a critical capability for manufacturers seeking stable production, tighter quality control, and measurable ROI. Although the process seems simple, delivering consistent, high-precision profiles requires coordinated control of melting, die flow, vacuum calibration, cooling, and downstream systems. As markets demand lower scrap, higher output, and better dimensional accuracy, factories are increasingly reevaluating how extrusion engineering directly impacts day-to-day stability and long-term profitability.

This guide summarizes the core engineering principles behind modern profile extrusion and explains how real manufacturers improved quality and ROI through better process control.

Why High-Precision Profile Extrusion Matters

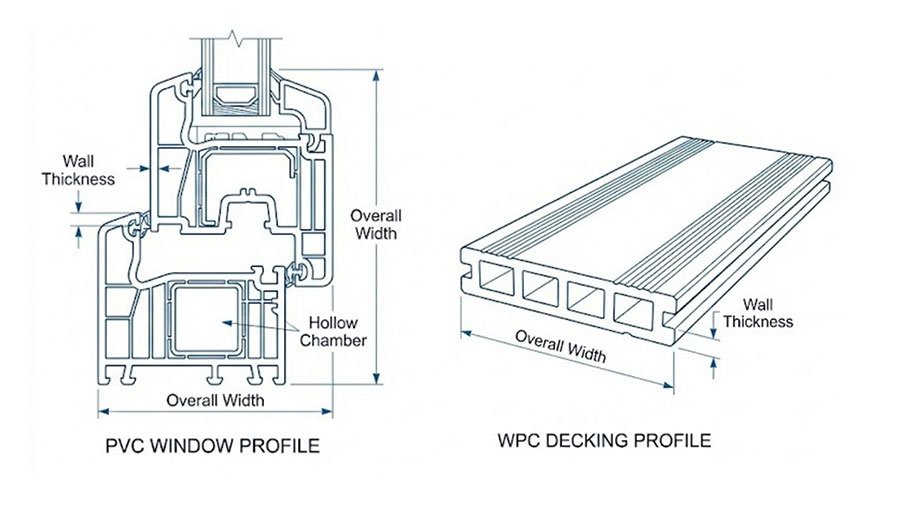

Profile extrusion supports a wide range of industries—construction, automotive, furniture, and general manufacturing. As product requirements grow more stringent, factories must deliver:

- Stable dimensions and appearance

- Lower defect rates

- Compatibility with recycled or filled materials

- Energy-efficient operation

- Predictable long-run performance

Older extruders often struggle with these expectations, especially with heat-sensitive or high-fill materials. Precision extrusion has become a strategic capability, not just a production method—especially for manufacturers planning to scale up or optimize their PVC Profile Extrusion Line.

Core Engineering Technologies That Drive Stability

Behind every high-performing profile extrusion line is a set of engineering technologies that work together to ensure stable output, consistent dimensions, and long-term reliability. The following core systems form the backbone of modern extrusion performance—and determine whether a line runs smoothly or constantly requires operator intervention.

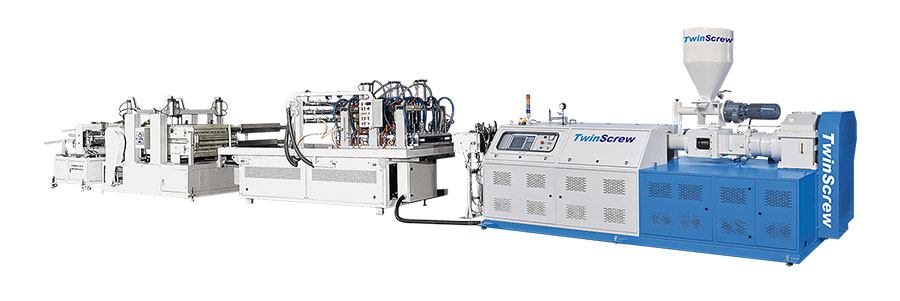

Twin-Screw Melting & Mixing

Today’s materials—PVC, PP, WPC, biodegradable blends—require controlled shear and uniform plasticization. Twin-screw extruders provide:

- Superior mixing & homogenization

- Enhanced temperature control

- Stable output pressure

- High tolerance for fillers & recycled content

Readers looking for deeper technical comparisons can review our article on the factors that affect twin-screw extrusion quality, which explains melt behavior and shear dynamics in more detail.

Die Engineering for Accurate Profiles

High-quality dies ensure:

- Balanced melt flow

- Sharp profile details

- Reduced bending, twisting, and warpage

Vacuum Calibration & Cooling

Once the melt exits the die, the profile is soft and unstable. Modern calibration systems:

- Lock geometry into place

- Maintain straightness

- Prevent shrinking & surface defects

Downstream Synchronization

A stable process requires well-coordinated:

- Haul-off traction

- Cooling system

- Cutting & stacking

These technologies work together to ensure consistent production.

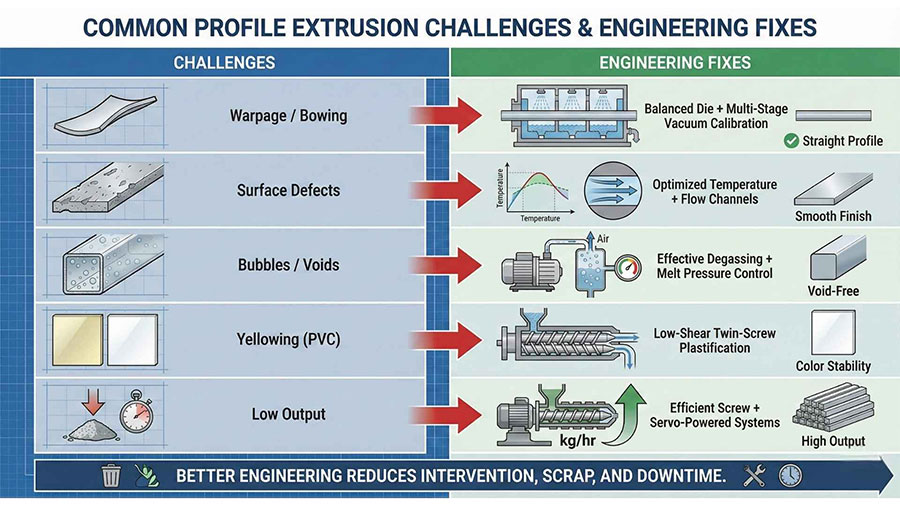

Common Profile Extrusion Challenges & Proven Solutions

Even well-designed extrusion lines face recurring technical challenges. What separates high-performing factories from unstable production is how effectively these issues are diagnosed and engineered out of the process. Below are the most common failure points—and the solutions proven to eliminate them.

| Challenge | Engineering Solution |

|---|---|

| Warpage / bowing | Balanced die + multi-stage vacuum calibration |

| Surface defects | Optimized temperature + flow channels |

| Bubbles / voids | Effective degassing + melt pressure control |

| Yellowing (PVC) | Low-shear twin-screw plastification |

| Low output | Efficient screw + servo-powered systems |

Better engineering reduces operator intervention, scrap, and downtime.

Real-World Case Studies: Why Engineering Quality Matters

While theory explains how extrusion should work, factories experience the reality—shifts, operators, raw material variations, and changing production targets. These real-world case studies demonstrate how engineering decisions directly affect stability, product quality, and ROI in daily operations.

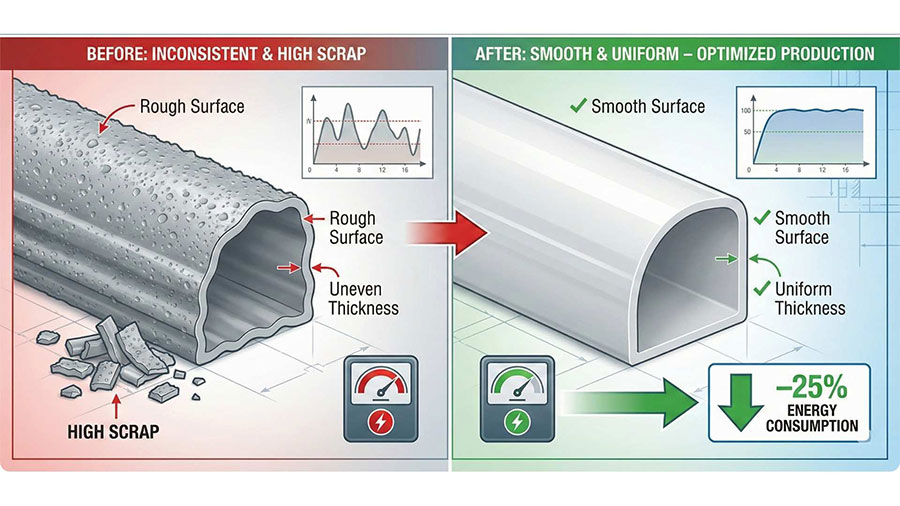

Case 1: PVC Decorative Profiles – Stabilizing Output

A Southeast Asian factory experienced inconsistent surface quality and high scrap. After upgrading:

- More uniform surface appearance

- Scrap dramatically reduced

- Energy consumption down 25%

Production became predictable instead of reactive.

* Results vary depending on configuration, material, and on-site production conditions. Actual performance improvements are confirmed after technical evaluation.

Case 2: PVC Ceiling Panels – Eliminating Yellowing

A manufacturer using single-screw extruders faced yellowing caused by thermal degradation. After transitioning to twin-screw:

- Melt temperature stabilized

- Yellowing disappeared

- Dimensional accuracy improved

Those exploring ceiling panel production can refer to our PVC Ceiling Machine Guide for more detailed process explanations.

Technical Overview: Configurations for Modern Profile Lines

Common configurations include:

- Extruders: 75 / 90 / 110 / 130 mm twin-screw

- Output: 150–1,200 kg/hr

- Materials: PVC, WPC, PP, ASA, PMMA, recycled blends

- Core Components: ABB/B&R, Schneider, Fuji

Twinscrew Industrial integrates screw geometry, die engineering, vacuum logic, and downstream synchronization to achieve long-term extrusion stability.

Buyers comparing configurations can also review our extended guide on how to choose the best PVC extrusion line for their production needs.

* All configuration details, output ranges, and component selections are flexible and may vary based on product geometry, target capacity, material formulation, and regional production standards. Final specifications are confirmed only after a technical review of your requirements.

Frequently Asked Questions About Plastic Profile Extrusion

Before moving to the final recommendations, here are concise answers to the questions buyers ask most when evaluating extrusion equipment.

Q1. What determines stable profile extrusion quality?

Stable melt pressure. Without it, dimensions drift or warp. Twin-screw systems maintain pressure much more consistently.

Q2. How do I prevent bending or warpage?

Most warpage comes from uneven cooling or misaligned calibration tooling.

Q3. Can one line produce multiple profile products?

Yes—ceiling panels, trims, window/door profiles, WPC boards, automotive strips, and more.

Q4. Why does PVC turn yellow?

Excessive shear heat. Low-shear twin-screw processing removes this issue.

Q5. What accuracy can I achieve?

±0.15–0.30 mm for PVC profiles; tighter for automotive applications.

Q6. How much energy can modern lines save?

Typically 8–15%, depending on configuration.

Q7. What materials are supported?

PVC, WPC, PP, biodegradable blends, recycled formulations.

Q8. What is the typical ROI timeline?

Many factories achieve ROI within months, especially after reducing scrap and energy consumption.

Q9. Do you provide installation & training?

Yes—full installation, commissioning, and on-site training.

Q10. Can the extrusion line be customized?

Absolutely, based on geometry, wall thickness, output, cooling requirements, and application.

All performance figures, energy-saving percentages, output ranges, tolerance values, and ROI timelines mentioned in this guide are reference estimates based on typical industry scenarios. Actual results may vary depending on material formulation, equipment configuration, tooling design, operator experience, and on-site production conditions.

Final specifications, performance, and cost calculations are confirmed only after a technical discussion and requirement review for your project.

We welcome international buyers to contact us for personalized engineering assessments and configuration proposals.

Build Your Competitive Advantage on Stable Extrusion

Profile extrusion is a precision-driven process where engineering quality determines profitability. Factories adopting modern twin-screw extrusion systems consistently see:

- Higher and more stable output

- Lower scrap and downtime

- Better surface finish and dimensional control

- Reduced operational cost

- Faster ROI

Whether you are upgrading an existing line or investing in a new one, the right engineering foundation will define your long-term competitiveness.For technical recommendations based on your profile design, material, or output goal, Twinscrew Industrial is ready to help.If you would like personalized engineering guidance or a configuration proposal, please feel free to contact us anytime.

Related Articles