PVC Pipe Making Machine & Production Line : Start Smart, Scale Fast

- Where Are PVC Pipe Making Machines Used?

- What Is a PVC Pipe Production Machine?

- Choosing the Right PVC Pipe Manufacturing Machine Configuration

- Planning Your PVC Pipe Manufacturing Layout

- Key Features of Our PVC Pipe Making Machines

- Project Spotlight : A Successful PVC Pipe Production Line in Dubai

- PVC vs. HDPE Pipe Production: Key Differences

- Frequently Asked Questions

- Why Choose Twinscrew for PVC Pipe Manufacturing?

- Thinking Beyond Pipe Production?

- Partner with the PVC Pipe Production Experts at Twinscrew

PVC pipe manufacturing is a high-demand, high-return business. Whether you're starting from scratch or expanding capacity, selecting the right PVC pipe making machine and building an efficient production line is the smartest way to scale fast and stay competitive. This guide walks you through the critical components, configurations, and ROI strategies trusted by manufacturers worldwide.

Where Are PVC Pipe Making Machines Used?

PVC pipe production systems are widely used across multiple industries due to the versatility and durability of PVC material—and similar extrusion principles are applied in specialized fields like medical tube extrusion, where precision and cleanliness are paramount.

- Residential and Commercial Plumbing – Water supply and drainage systems

- Electrical Conduit Systems – Cable protection and routing

- Agricultural Irrigation – Low-pressure water delivery and drip systems

- Industrial Applications – Chemical fluid transportation

- Sewage and Wastewater Systems – Underground pipe networks

Each application demands precision, consistency, and durability—qualities essential in a medical tube extrusion line setup, where Twinscrew’s modular systems can be adapted for high-precision medical use.

What Is a PVC Pipe Production Machine?

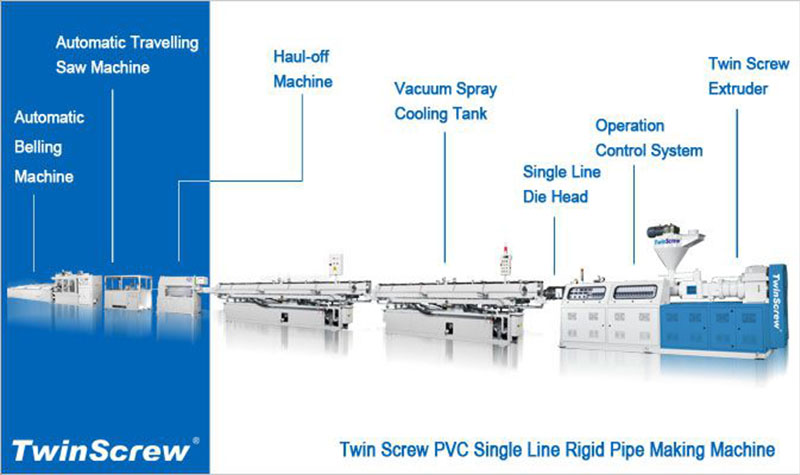

A PVC pipe extrusion line is a continuous system that transforms raw PVC compounds into durable, dimensionally accurate pipes—ensuring consistent quality from material feeding to final cutting.

- Twin Screw Extruder

- Spider Die Head

- Vacuum Calibration & Cooling Tank

- Haul-off Machine

- Cutter

- Belling Machine or Tip Table

Each machine plays a vital role in ensuring high-output and consistent pipe quality.

Choosing the Right PVC Pipe Manufacturing Machine Configuration

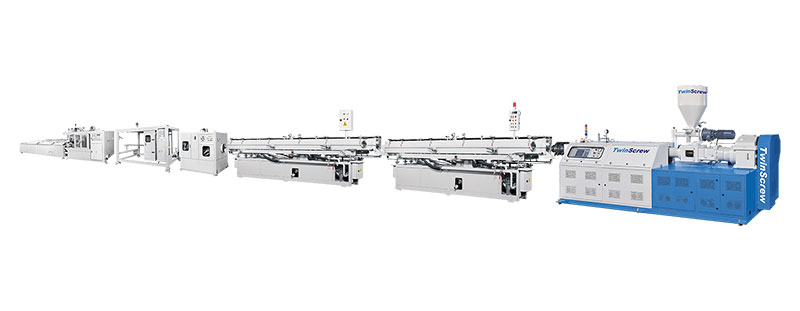

Twinscrew offers two primary types of PVC pipe making machines, both powered by robust PVC twin screw extruders designed for stable output and optimized compounding efficiency.

-

Dual Line PVC Pipe Making Machines

Ideal for manufacturers seeking higher throughput with a compact footprint

Model Suitable Pipe Diameter Output Capacity Material TSE-75-RP-S 20 – 110 mm 150 – 250 kg/hr PVC Compounding TSE-90-RP-S 75 – 160 mm 350 – 450 kg/hr PVC Compounding TSE-110-RP-S 200 – 450 mm 500 – 800 kg/hr PVC Compounding TSE-130-RP-S 200 – 630 mm 600 – 1200 kg/hr PVC Compounding -

Single Line PVC Pipe Production Machines

Perfect for flexible pipe sizes and small-to-medium scale setups.

Model Suitable Pipe Diameter Output Capacity Material TSE-75-RP-S 60–160 mm 150 – 300 kg/hr PVC Compounding TSE-90-RP-S 90–250 mm 300 – 450 kg/hr PVC Compounding TSE-110-RP-S 160–400 mm 300 – 450 kg/hr PVC Compounding TSE-130-RP-S 400–630 mm 800 – 1000 kg/hr PVC Compounding Twinscrew’s modular configurations and precision engineering allow manufacturers to start smart with manageable investment, while providing the capacity and flexibility to scale fast as demand grows.

Planning Your PVC Pipe Manufacturing Layout

Efficient space planning is essential when setting up your PVC pipe manufacturing facility. A typical layout includes:

-

Material Mixing Area

– High-speed mixers and storage silos -

Extrusion Zone

– Twin screw extruder, die head, calibration, and haul-off -

Cooling Section

– Water spray tanks and vacuum calibration -

Cutting and Belling

– Pipe cutters and socketing units -

Inspection & Storage

– Quality control and warehouse

Optimizing layout increases production efficiency and prepares your factory for future scaling.

Key Features of Our PVC Pipe Making Machines

At the heart of our PVC pipe production machines is a precision-engineered twin screw extruder, selected from different types of twin screw extruders to match specific pipe sizes, output levels, and material requirements.

- Spider Die technology for uniform melt flow

- Advanced temperature regulation

- Sealed water cooling with vacuum calibration

- Modular add-ons for slotting, belling, or eco-materials

These innovations ensure stable output, high energy efficiency, and consistent pipe dimensions.

Project Spotlight : A Successful PVC Pipe Production Line in Dubai

A client in the UAE partnered with Twinscrew to launch a new plant for producing 110–250 mm rigid uPVC pipes. We delivered a TSE-90-RP-S Dual Line, fully equipped with spider die, non-dust cutter, and auto belling system.

- Operational within 6 weeks

- Output: 400 kg/hr per line

"Twinscrew’s team was fast, responsive, and highly professional. Their support during installation and training made a huge difference." — Factory Manager, UAE

PVC vs. HDPE Pipe Production: Key Differences

Understanding the difference between PVC and HDPE extrusion helps buyers choose the right technology :

| Feature | PVC Pipe Extrusion | HDPE Pipe Extrusion |

|---|---|---|

| Extruder Type | Twin Screw | Single Screw |

| Temperature Range | Lower | Higher |

| Applications | Plumbing, Drainage | Gas, Water Mains |

| Rigidity | Rigid | Flexible |

| Material Cost | Lower | Slightly Higher |

Twinscrew focuses on rigid PVC pipe production but can consult on hybrid setups.

Frequently Asked Questions

-

Can I use CPVC or biodegradable compounds?

Yes, our machines can support CPVC, starch-based, and cellulose-based materials. However, processing these materials may require specific screw designs, temperature control systems, or add-on modules. Please consult with our team to select the right configuration for your needs.

-

What’s the average installation time?

From production to setup, expect 6-10 days including training.

-

Can I customize the machine layout to fit my plant?

Absolutely. We offer layout planning and machine customization services to match your factory space, utility setup, and process flow.

-

How do I maintain consistent pipe quality over long runs?

Our twin screw extruders feature stable temperature control and pressure regulation. We also offer optional inline monitoring tools (e.g., wall thickness gauges, OD sensors) to help ensure consistent product quality throughout production.

Why Choose Twinscrew for PVC Pipe Manufacturing?

With over 1,200 twin screw systems installed worldwide, Twinscrew is your trusted partner in PVC pipe production. Benefits include:

- 35+ years of extrusion expertise

- Global support network

- Tailored solutions for PVC, CPVC, PE, PP, and biodegradable plastics

- In-house manufacturing of core parts

Thinking Beyond Pipe Production?

If you're also exploring how to process raw PVC into pellets before extrusion, check out our Beginner’s Guide to PVC Pelletizing Extrusion Lines. This guide walks you through the fundamentals of pelletizing systems, including die-face cutting, strand cooling, and automatic feeding for efficient compound preparation.

Partner with the PVC Pipe Production Experts at Twinscrew

Ready to start smart and scale fast in the PVC pipe manufacturing industry? Whether you need a compact PVC pipe making machine or a full-scale production line, Twinscrew delivers proven solutions backed by decades of expertise. Contact us today to explore a system tailored to your goals.

Related Articles