PVC Profile Extrusion Lines: Twin-Screw Process, Benefits & Applications

- What Is a PVC Profile Extrusion Line?

- PVC Profile Extrusion Process – Step by Step

- Twin-Screw vs. Single-Screw Extruders

- Inside a Twin-Screw PVC Profile Extrusion Line: Technology That Drives Results

- How Twin-Screw Design Solves Common Extrusion Challenges

- Industrial Applications of PVC Profiles

- Choosing the Right Extrusion Line for Your Needs

- Taking the Next Step with Your PVC Profile Extrusion Line Investment

PVC profile extrusion plays a vital role in today's industrial landscape, powering the efficient production of durable, sustainable components like window frames, decorative trims, cable conduits, and more. As market demand for high-performance materials grows, manufacturers are turning to advanced PVC extrusion lines powered by twin-screw technology.

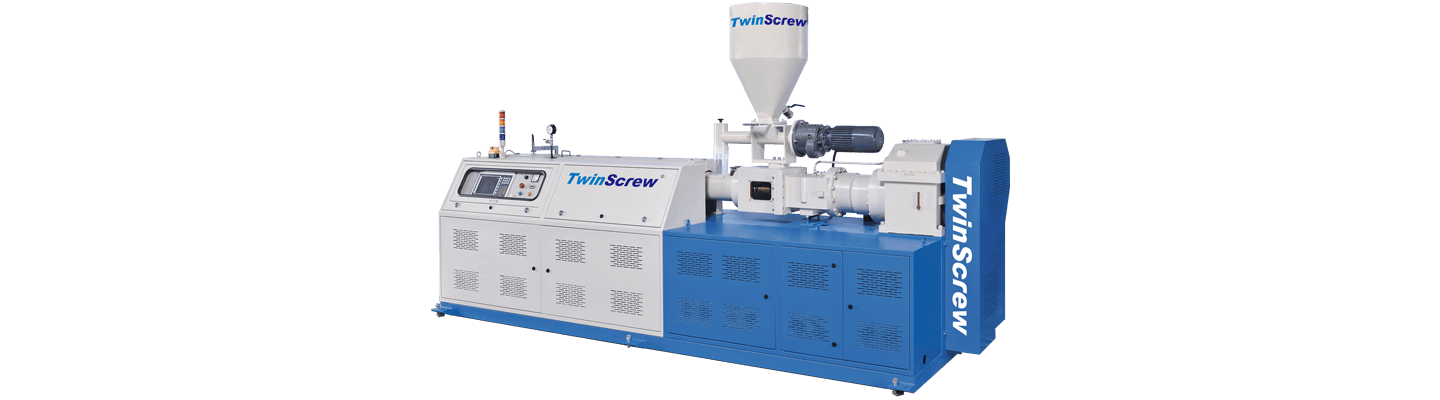

With over 30 years of engineering expertise, TwinScrew has emerged as a global leader in twin-screw extrusion, delivering high-precision systems that meet the needs of low-carbon, high-efficiency production. This guide provides a comprehensive overview of the PVC extrusion process, outlines key system components, compares extrusion technologies, and explains how manufacturers can achieve superior quality, throughput, and cost-efficiency by choosing the right equipment.

If you're short on time, get a quick overview with our PVC Twin Screw Extruders: A 3‑Minute Guide.

What Is a PVC Profile Extrusion Line?

PVC profile extrusion lines are the foundation of modern plastic manufacturing. This section explains what these systems are, their core components, and how each part contributes to producing high-quality PVC profiles.

To understand how manufacturers achieve consistent product quality and operational efficiency, it’s important to first break down what a PVC profile extrusion line actually is.

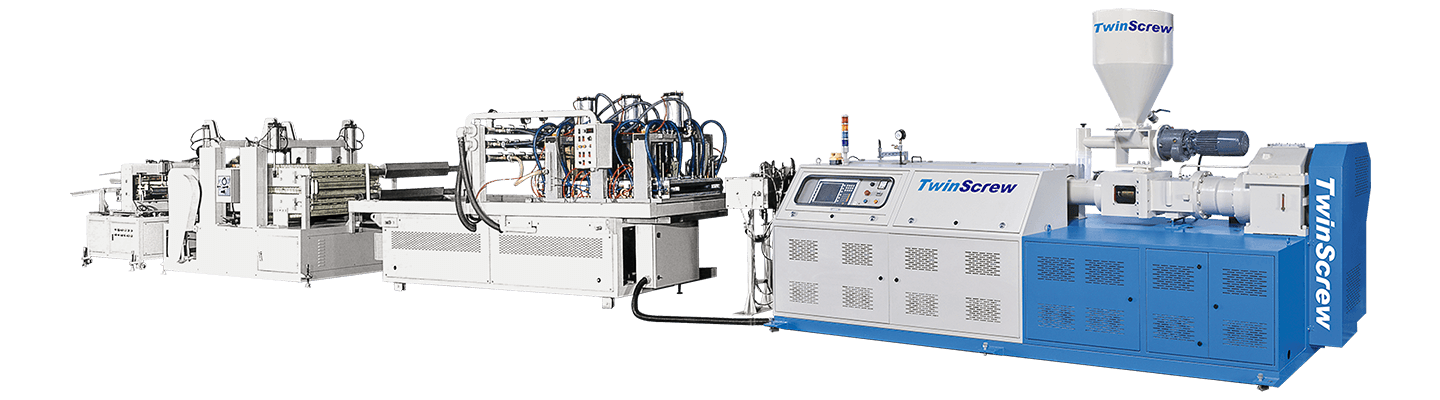

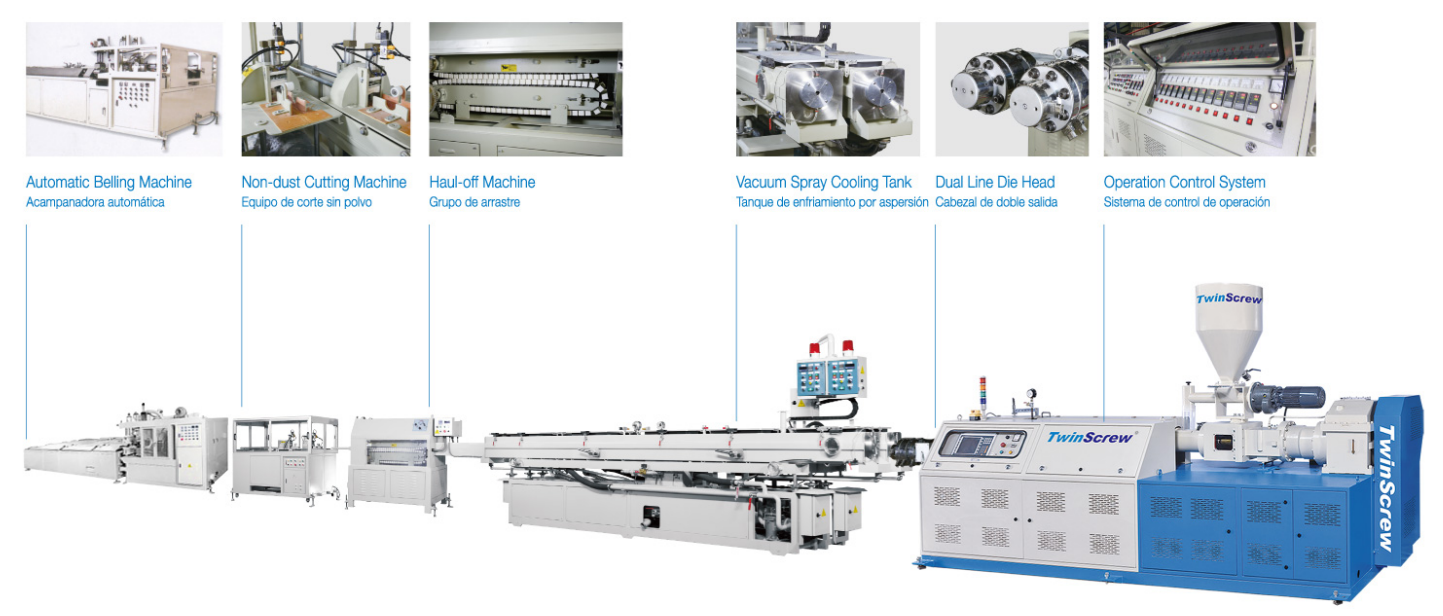

A PVC profile extrusion line is a fully integrated production system that transforms raw PVC resin into continuous, dimensionally stable profiles. The core components include:

-

Extruder (Twin-Screw or Single-Screw)

: Melts and homogenizes the PVC compound using heat and mechanical shearing. -

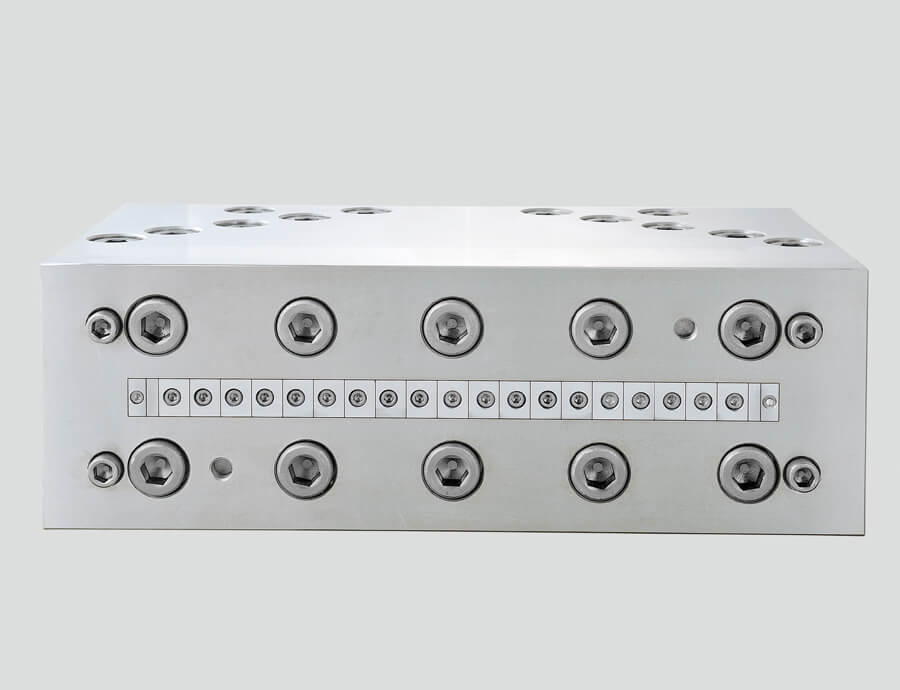

Extrusion Die

: Shapes the molten plastic into precise profiles, ensuring uniform flow, consistent temperature, and shear distribution. -

Calibration & Cooling System

: Vacuum tables and water baths solidify and stabilize the profile, preventing warping and internal stress. -

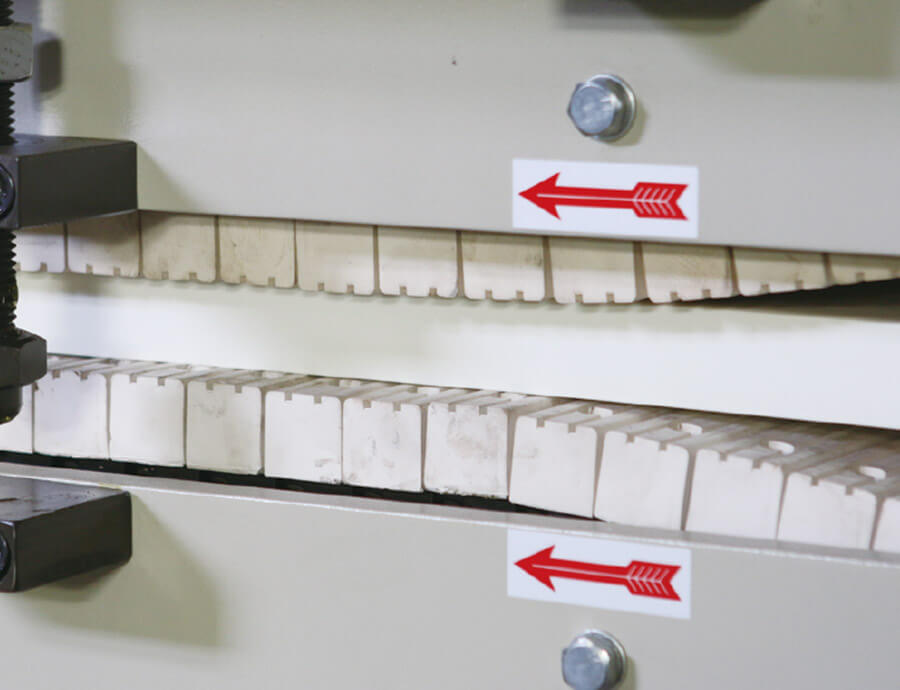

Haul-Off Unit

: Pulls the profile through the line at a controlled speed to maintain dimensional accuracy. -

Cutting Unit

: Cuts the profile into exact lengths for final packaging or downstream use.

PVC Profile Extrusion Process – Step by Step

Understanding the PVC extrusion process is crucial for achieving consistent product quality. Here we break down each step, from raw material preparation to final product cutting, and highlight where twin-screw technology makes a difference.

Now that we’ve reviewed the key components of an extrusion line, let’s take a closer look at how each one contributes to the full manufacturing process.

-

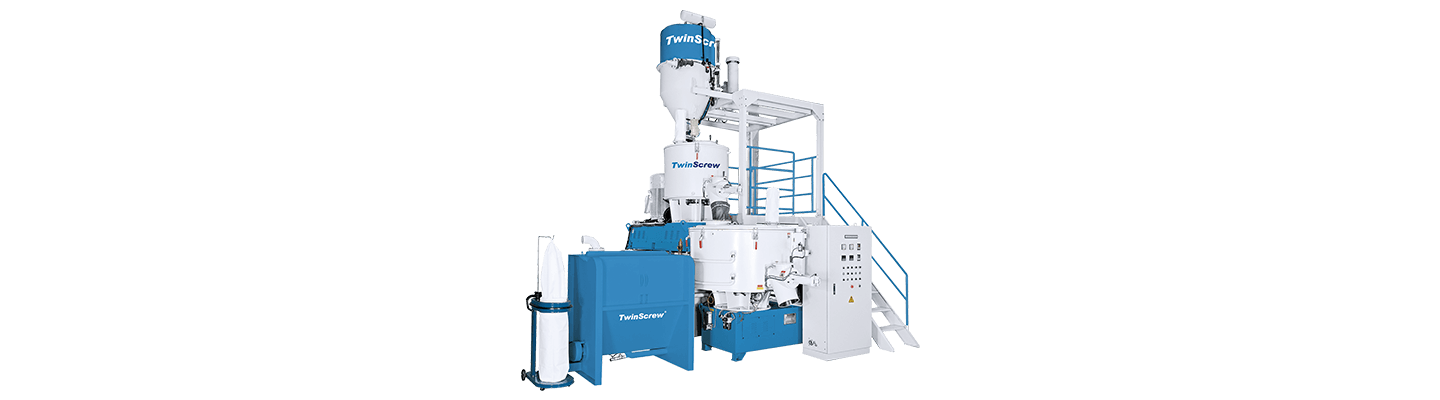

Compounding and Preparation:

PVC resin is blended with stabilizers, lubricants, colorants, and fillers. The quality and uniformity of this compound directly impact the final product's strength, color, and durability.

Read more : PVC High Speed Mixer & Vertical Cooling Mixer

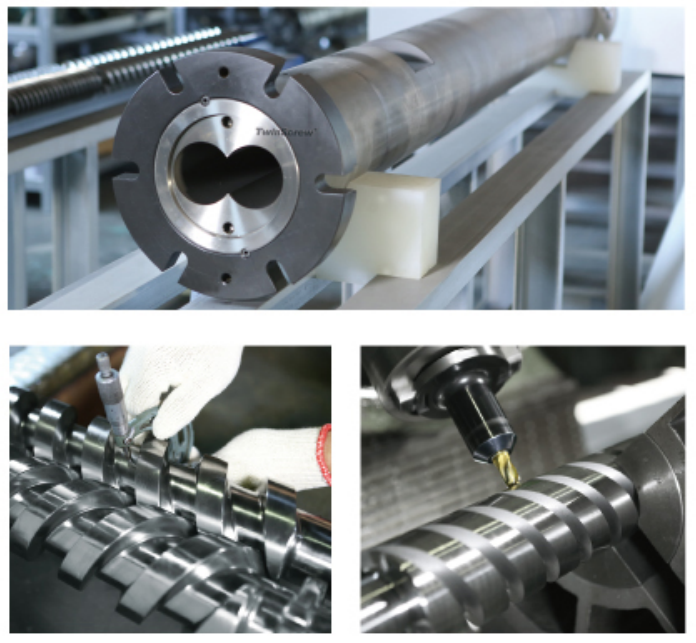

Melting, Mixing, and Degassing:

The compound enters the heated barrel of the extruder, where twin intermeshing screws generate intense kneading and shear. This ensures thorough dispersion of additives. Strategically placed degassing zones remove volatile gases and trapped air, preventing voids and surface defects.

Read more : Extruder Screws and Barrels -

Precision Shaping:

The homogenous melt is forced through a precision-engineered die that defines the profile’s shape. The die compensates for extrudate swell and ensures uniform dimensions across the entire output.

-

Calibration and Cooling:

The hot profile enters a vacuum calibration table and water bath system, where it is cooled and fixed to exact dimensions. This stage is critical for avoiding warping, bowing, or internal stress deformation.

-

Finalization:

A synchronized haul-off unit maintains line speed, while the cutter slices the finished product into exact lengths. The result is a dimensionally stable, defect-free PVC profile ready for packaging.

Twin-Screw vs. Single-Screw Extruders

Choosing between a single-screw and a twin-screw extruder affects your production quality, speed, and versatility. This section compares both technologies and outlines why twin-screw extrusion is often the superior choice for PVC profiles.

The success of each production step depends heavily on the extruder. Understanding the mechanical differences helps identify the best system for your product mix and operational goals.

| Feature | Single-Screw | Twin-Screw |

|---|---|---|

| Mixing Capability | Limited | Excellent – Intensive shear and kneading |

| Material Versatility | Basic compounds only | Advanced – Heat-sensitive & high-filler PVC |

| Output Consistency | Variable | Stable – High-quality, uniform profiles |

| Throughput & Speed | Moderate | High – Faster cycles with better melt quality |

For a closer look at the configurations available, see our detailed comparison on the Types of Twin Screw Extruders.

Inside a Twin-Screw PVC Profile Extrusion Line: Technology That Drives Results

While twin-screw technology excels across many extrusion applications, its role in PVC profile production is particularly transformative. A dedicated TwinScrew PVC profile extrusion line offers not just superior compounding but also unmatched control over material flow, pressure, and output consistency.

TwinScrew’s extrusion lines are custom-built for PVC profiles, supporting both rigid and foam-core products with high-filler formulations or heat-sensitive additives. The intermeshing screw design ensures uniform material dispersion, while integrated degassing zones eliminate air pockets and volatiles that often cause dimensional instability.

These lines come equipped with precision dies tailored to each profile type, along with calibration tables and cooling systems optimized for exacting tolerances. The result? Profiles with excellent surface finish, tight dimensional control, and outstanding mechanical strength—ready for use in demanding construction, electrical, or industrial applications.

How Twin-Screw Design Solves Common Extrusion Challenges

Beyond performance comparisons, the real value of twin-screw design lies in its ability to solve production challenges that impact quality, reliability, and profit margins.

Common extrusion issues include:

-

Melt Fracture

: Caused by excessive shear, leading to surface roughness. Twin-screw systems control shear forces and heat more effectively. -

Voids & Air Traps

: Air bubbles compromise structural integrity. Degassing zones in twin-screw systems eliminate this issue at the source. -

Warping & Dimensional Inaccuracy

: Poor cooling control causes profile deformation. Twin-screw systems ensure uniform heat distribution and enable precision cooling downstream.

Real-World Example: PVC Gutters

Well-designed extrusion lines eliminate common gutter defects like sagging and buckling. With optimized calibration, even large hollow profiles maintain mechanical strength under thermal stress and UV exposure.

For a full breakdown of how gutter extrusion machines work and why PVC is replacing metal in modern construction, read our article: Gutter Extrusion Machines: A Guide to Modern Plastic Gutter Manufacturing.

Industrial Applications of PVC Profiles

With a better understanding of how twin-screw systems address quality issues, let’s explore where these high-performance PVC profiles are being used across different industries.

-

Construction

: Energy-efficient window frames, door profiles, cladding, vinyl siding. -

Electrical Systems

: Cable trays, conduit covers, trunking with excellent insulation. -

Furniture & Interior

: Decorative trim, edge banding, wall panel profiles. -

Medical

: Twin-screw systems are widely used in medical tube extrusion for applications requiring extreme precision and sterilization compliance. -

General Industry

: Sealing strips, tubing, foam-filled profiles for structural or flexible applications. -

Infrastructure

: These lines can also be adapted for large-scale piping systems using a PVC Pipe Making Machine.

Each of these applications demands dimensional accuracy, consistent surface finish, and long-term durability—all made possible through precision extrusion.

Choosing the Right Extrusion Line for Your Needs

As PVC profiles serve increasingly diverse industries, selecting the right extrusion line becomes a strategic decision that affects both product quality and market competitiveness.

When evaluating a line, consider:

-

Extruder Type

: Twin-screw offers superior performance for complex or high-volume production. -

Formulation Flexibility

: Choose systems that handle rigid, flexible, foam-core, or high-filler materials. -

Output Needs

: Ensure capacity and line speed match your throughput goals. -

Support & Maintenance

: Look for vendors who offer in-house component production and responsive after-sales service.

If you're producing masterbatch or compound granules, consider integrating a PVC Pelletizing Extrusion Line to streamline upstream preparation.

Twinscrew manufactures all key components—screws, barrels, gearboxes—in-house. This ensures faster lead times, tight quality control, and lifetime machine reliability.

Taking the Next Step with Your PVC Profile Extrusion Line Investment

A high-quality PVC profile extrusion line is more than just equipment—it's a strategic asset that can drive product innovation, operational efficiency, and long-term growth. Whether you're upgrading existing production or planning a new extrusion facility, the right technology partner makes all the difference.

At Twinscrew, we specialize in custom-engineered twin-screw extrusion systems backed by 30+ years of in-house manufacturing expertise and global service support.

Ready to start building your next-generation extrusion operation?

Contact our technical team today for personalized consultation, machine recommendations, and turnkey system solutions tailored to your production goals.

Related Articles